Chemical Resistance Guide

For more details about chemical resistance, please check our Rubber Chemical Resistance Guide.

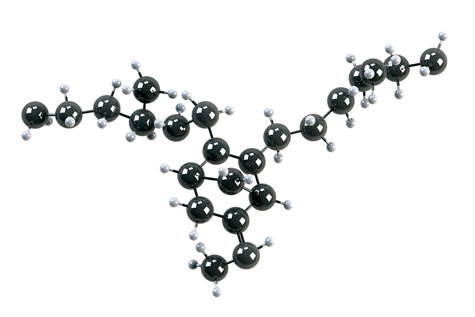

Ethylene propylene diene monomer (EPDM) is a versatile terpolymer synthetic rubber. EPDM has a high acceptance in the sealing industry due to its wide temperature range, as well as its excellent resistance against ageing and weathering, steam, and a wide range of chemicals.

EPDM is available in general industry types, and also in specific types for industries such as food & beverage, pharmaceuticals, and potable water.

A significant differentiation within the EPDM family lies in its curing system. EPDM can be cured using two primary methods:

Peroxide cured EPDM, often abbreviated as EPDM PC, is known for its temperature and steam resistance compared to sulfur cured EPDM (EPDM SC). The process of peroxide curing of rubber, particularly in the case of EPDM, enhances its chemical and thermal stability.

The differences between both sulfur curing (SC) and peroxide curing (PC) systems are mentioned in the next chapters.

For more details about chemical resistance, please check our Rubber Chemical Resistance Guide.

ERIKS NV

P.O. Box 19108

3501 DC Utrecht

The Netherlands

E info@eriks.com

37 01 32 89

VAT Number

NL003.076.490.B02