In this article

The importance of hygienic design in the food industry

Anyone working in the food industry knows that proper hygiene is an absolute must at all times. The Netherlands is a frontrunner in food safety production and hygienic design. Did you know that Dutch machine builders are responsible for 11% of the world's production of all food processing machines? On top of that, over 20% of the total Dutch production is food-related. The food industry is an important export product - the cornerstone of the Dutch industry.

Give micro-organisms no chance

In this blog, we will illustrate the importance of hygienic design. When designing or building plants, equipment, machinery, production lines or components for the food industry, it is crucial to give micro-organisms as little chance as possible. Food safety, food quality and the prevention of food contamination are key.

Poorly hygienically designed equipment is difficult to clean. Residue can accumulate in dead spaces, allowing micro-organisms to grow. Cleaning agents and disinfectants may pile up too, affecting the equipment or even migrating into product batches.

The technical functions and features of equipment must fully comply with hygiene requirements right from the design stage. For example, the location of electrical components and cleaning capabilities of the entire production line must be taken into account. The Machinery Directive in the food industry describes multiple hygiene requirements. These requirements are listed in NEN-EN 1672-2 and ISO 14159.

EHEDG: the most important international branche organisation

Hygienic design goes beyond following standards and guidelines. The European Hygienic Engineering & Design Group (EHEDG) - a non-profit consortium of machine builders, food companies, food industry suppliers, research institutes, universities and government agencies - educates about hygienic design. EHEDG provides guidance on national and international legislation. ERIKS is a EHEDG member.

Solid design prevents future problems

If you take the guidelines for hygienic design as a starting point, you are in fact determining your future strategy (and that of the entire chain) for food production as a whole. It is more effective to incorporate hygiene requirements into your design immediately than to modify established concepts at a later stage. Changing the design requires more time and can lead to production downtimes, which can be very costly. Solid hygienic design guarantees product safety, ensures long service life, simplifies cleaning and maintenance and minimises the Total Cost of Ownership.

Focus areas for hygienic design

- Elimination of micro-organisms and pests in the production process

- Elimination of contamination risks

- Correct material selection

- Smooth contact areas and streamlined design

- Hygienic welding

- Correct after-treatment of materials

- Cleaning methods

- Inspectability of systems and components

- Environmental conditions (wet/dry)

- Closed and open production systems

Take all these points into account in the design phase and benefit from an easier process of design, construction, operation and maintenance of your production line or machine.

Advice on design and material selection

Do you need advice on installation, or help selecting valves, bearings, plastics, seals, rubber molded parts, drives, conveyors, filters or food hoses? Our product specialists are here to help. We also have in-depth knowledge of your applications. Thanks to our thorough knowledge of your systems, we can advise you on existing designs or help co-engineer new hygienic designs for your production lines in dairy plants, bakeries, breweries, vegetable processing plants or packaging lines. As a practical example, Peter Kuys talks about our assembly method for fitting couplings on food hoses.

Sanitary hoses and couplings to prevent bacterial growth

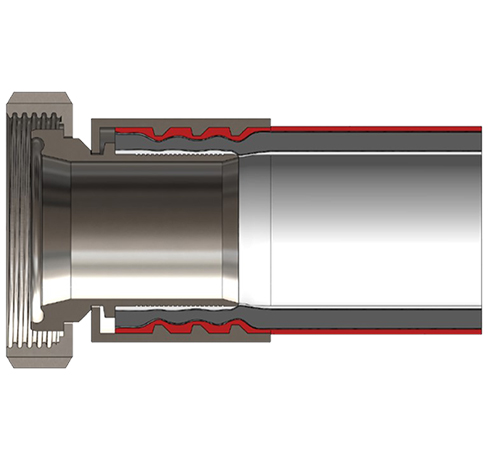

Food industry hoses always consist of at least three parts: a flexible hose with two (identical or varying) couplings. When pressing couplings to rubber hoses, it is vital that the seal is 100% tight. On top of that, a smooth transition between the hose connector and the inner wall of the hose is required: gaps between both parts irrevocably cause a build-up of bacteria, making it difficult to clean.

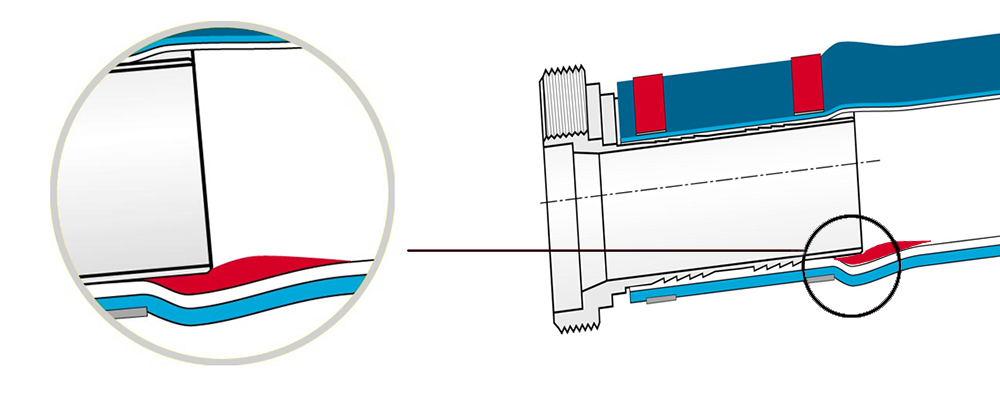

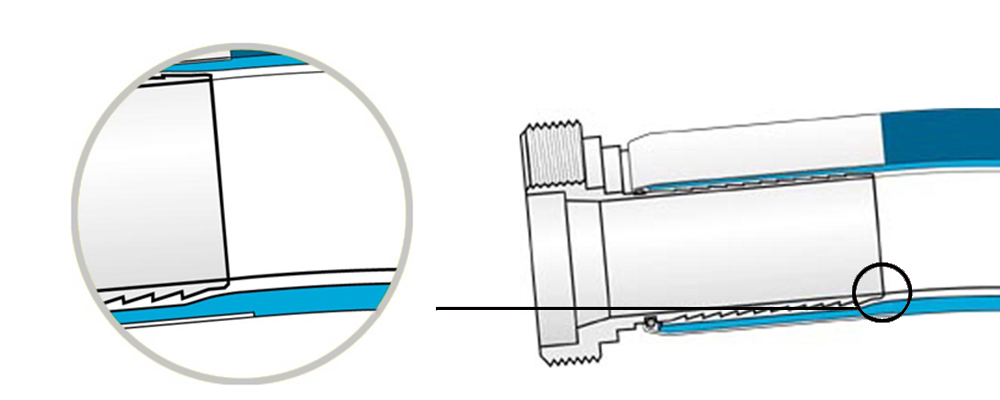

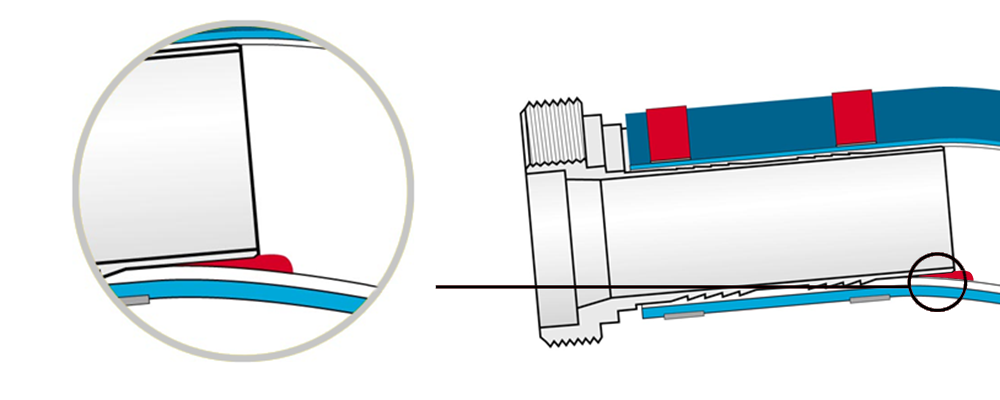

The profiles of the hose pillars and press sleeve must be compatible in order to obtain a correct compression. The crimp sleeve is slightly longer than the hose barb, so that the inner wall of the hose is pushed around it. This creates a functional smooth transition. Only a well-matched mix of parts will prevent the accumulation of debris.

Example of a correctly fitted coupling on the hose

Close up of hose stem/hose connection

The white inner wall seamlessly fits into the hose stem

Customers regularly ask me: "Why don't you use clamp couplings, that's much easier, isn't it?"

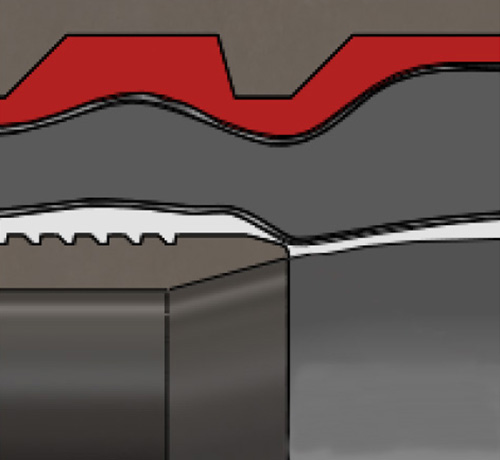

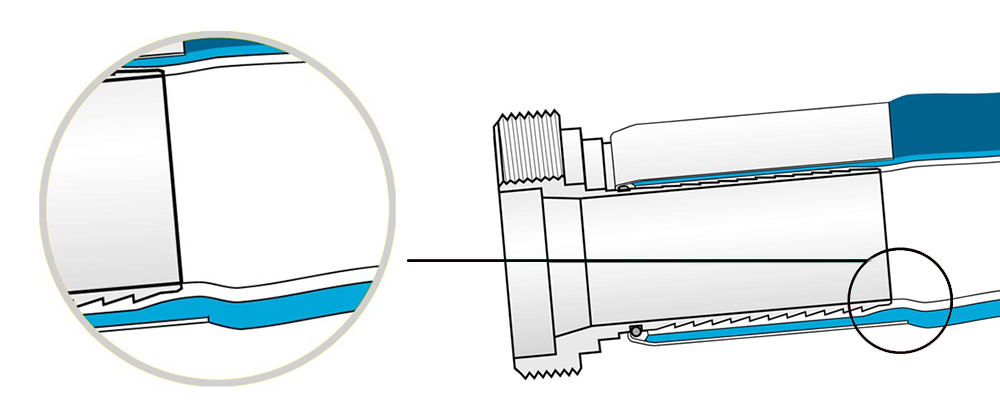

My response is simple and clear. Using clamp couplings is easier, but not hygienic. Crimp-sleeves are the only assembly method that achieves a hygienic connection. Look at the illustrations below to figure out why pressed coupling are preferred over clamping shells. The illustrations show pressure and bending as the environmental factors.

Differences between pressed couplings and clamping shells

Performance under pressure

Pressed connection

Connection with clamping shells or clip bindings

Bending Performance

Pressed connection

Connection with clamping shells or clip bindings

When pressure is increased or the hose is bent, no dead spaces can be seen on the hose fitted with a pressed connection. The hose with clamping shells shows a gap in which debris can accumulate.

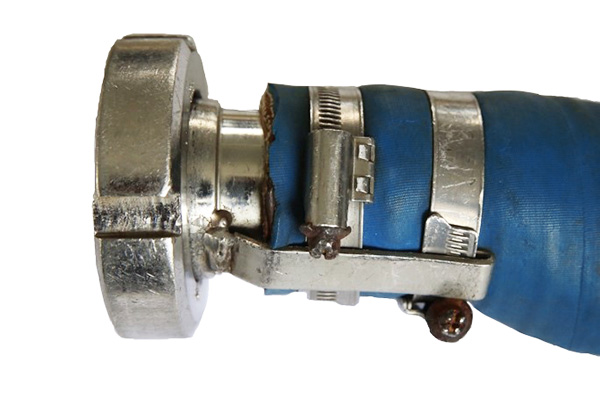

Use of hose-clamp leads to bacterial growth

Photos below show clamps that have been used for a few months, portraying the deformation and bacterial growth between the hose connector and inner wall.

© Burggraaf & Partners 2020

This example illustrates why we opt for compressed hose couplings for supply hoses.

Subscribe to our newsletter:

For the latest industry news and updates.