In this article

How to Improve your Total Cost of Ownership

Spending 10 times more on a component may seem counter intuitive to saving costs, but it could save you over a half a million Euros in the long run. When thinking of making cost savings, reducing the product purchase cost is often considered first. But this could lead to a false economy. Instead, the Total Cost of Ownership (TCO) should be reviewed as this will result in more significant savings in the long term.

TCO is much more than simply purchase price and it incorporates all the costs that may arise during a product’s lifetime. These can include, purchasing, stock and logistics - as well as administration, maintenance, repairs and final disposal, among others.

Identifying TCO is often only discussed when there is a problem with a machine. However, to make the most impact consider it from the start of the investment.

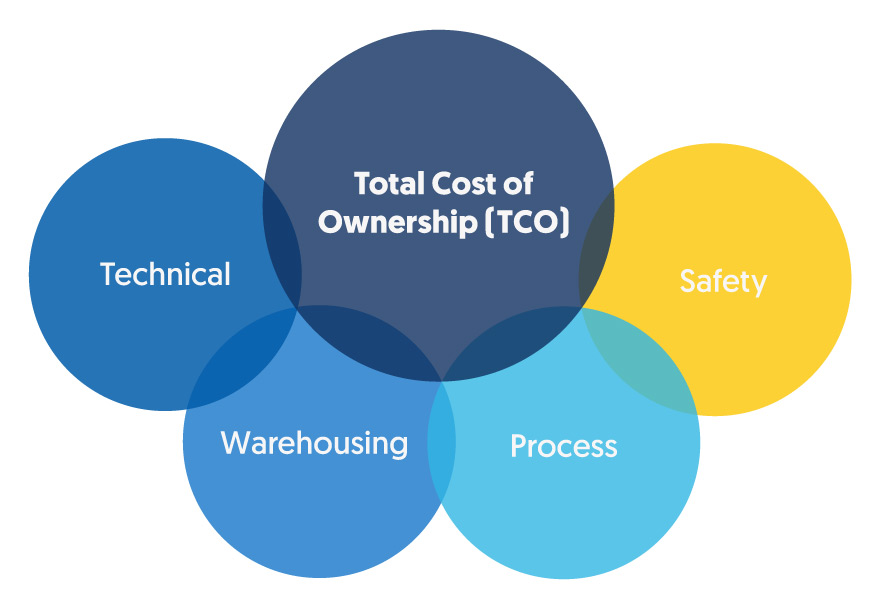

There are four key areas where TCO can be reduced:

Let’s take a closer look at the considerations to take and how to identify opportunities to reduce TCO.

Technical

When it comes to the technical aspect, it’s vital to have the right product in the system. Using components such as valves and hoses that cannot withstand the demands of the application means that you face premature failure and frequent breakdowns. Each time this happens there is costly unplanned downtime associated.

Minimising downtime

You may initially think that a cheaper product will be more cost-effective. But it will often not perform as well, or last as long as a more expensive part. Achieving longer lifetimes is most important with regards to reducing TCO. If you can expand the time between maintenance and service intervals you can improve your TCO substantially. A product with a higher purchase cost is likely to have enhanced performance, which results in less maintenance costs.

Spend 10x more to save €500.000

A cocoa processor was experiencing leaking o-rings in a chocolate press and had to carry out corrective maintenance on average 4 times per week. The cost of new products and maintenance was more than€625,000 per year. This comprised of approximately €1,600 product cost, €27,500 labour cost, and staggering production downtime costs of €596,000 as shown in the calculations table 1.

By changing the o-ring to a high-end product manufactured from a material with exceptional thermal and chemical resistance, the company was able to improve the machine’s performance. As a result, the company only had one leaking o-ring per month.

Using this new o-ring reduced maintenance costs dramatically, to less than €38,000 per year. That calculates to be a saving of over €587,000 per year!

In this case, the cost of the new o-ring was 10 times the cost of the original one. However, you can clearly see the impact it had on reducing labour costs to just €1,275 and downtime cost to €27,540.

It is not simply the cost of the component that you need to consider, but the wider impact on maintenance. Previously the service team always had to be on standby in case the part failed. With the new o-ring, these personnel costs could be reduced.

Old O-rings |

New O-rings |

Material Cost

(Preventative Maintenance)

940.44 euro/year

8,652.54 euro/year

Material Cost

(Replacement)

652.24 euro/year

362.45 euro/year

Labour Cost

27,591 euro/year

1,275 euro/year

Downtime Cost

595,965.60 euro/year

27,540 euro/year

TOTAL

625,149.28 euro/year

37,829.99 euro/year

TOTAL SAVING

587,319.28 euro/year

Table 1. The cost of replacing o-rings

Material considerations

When reviewing components, it’s important to consider how the material will perform during the whole process of operation and washdown. This is dependent on the environment, for example, pressure, temperature and the medium (i.e. if it is a gas or liquid). In the food and beverage, and pharmaceutical industries, there are often rigorous cleaning schedules and this puts an additional strain on materials as they are exposed to harsh cleaning chemicals.

Focus on preventing problems

By preventing problems from the outset, you can avoid costly downtime. Consider too what downtime means for your service level agreements with customers? Will you be in breach of any contracts should you experience downtime and not be able to deliver. Will there be costly financial penalties for this that you can’t risk taking?

Safety

When considering TCO it pays dividends to ensure you are following best safety practices. Inadequate safety measures could lead to injury and costly downtime if personnel are unable to work. Be aware of all the safety regulations, and make sure you are adhering to these.

Consider the environment staff work in and what personal protective equipment (PPE) they require. For example, are the gloves, ear defenders, safety goggles or boots suitable for the job at hand? Are the boots hardwearing enough? Similarly to technical components, the cheapest option will not necessarily be the most cost effective in the long run. Cheaper boots may wear out more quickly and need replacing more often at greater cost in the long term.

It pays to standardise

Standardising on products and purchasing in high quantities means you are more likely to receive and benefit from a bulk discount and buying efficiencies, which contributes towards reducing TCO.

Standardisation also has advantages when it comes to achieving safety certifications. For example, rather than having 25 different types of o-ring, you can realise efficiencies and reduce TCO by standardising on as few as you can. It is much easier and more time-efficient to gain certifications for three products compared to 25.

Process

Admin tasks are crucial in any business, but can be incredibly time consuming. Considering ways in which these tasks can be streamlined and made easier will help improve efficiencies and reduce TCO.

Optimising the purchasing process is key here. Efficiencies with procurement can be increased by reviewing and incorporating a number of different approaches, such as a using vending machines or electronic data interchanges (EDIs).

Utilising vending machines

Vending machines help keep costs to a minimum. Using vending machines for consumable stock provides users with easy access to equipment 24/7 without having to complete purchase orders and seek quotes each time a new item is required. Vending machines can even be set up with personalized smartcards, meaning every employee gets the right equipment and at the right time. For example, even when they are on the night shift and there is no warehouse manager present.

Stock levels can be easily tracked using software and replenished regularly so that personnel don’t run out of critical tools, PPE and accessories. The risk of human errors with manual tracking can also be reduced. In our experience, we have found that employees use less items when a vending machine was implemented, which we suspect is because their product use can be tracked.

Vending machines provide users with easy access to equipment 24/7.

Integrating electronic data interchanges

Consider too setting up purchasing agreements with suppliers. By linking your ERP system directly to your suppliers’ system makes it easier for staff to purchase equipment as and when is needed. With EDI, purchase orders and invoices etc, can be securely and accurately exchanged online directly between the you and your supplier using standardised forms. This provides an easy way for personnel to select and order parts as they are needed and reduces the time spent on paperwork.

Warehousing

When operating on the basis that equipment and components will fail regularly, spare parts always need to be kept on hand. But having to purchase all these spares and stock them inevitably adds costs to your business. In fact, research from ERIKS shows that 10% of budget is wasted as it is spent on unnecessarily duplicated parts*.

There is often low turn-over with some products and they might be left on the shelf for years, eventually becoming unusable. This is a significant waste and an area for TCO reduction. By carefully managing your spare parts inventory, means you can reduce your capital costs.

Correctly labelling parts and making sure identical looking components (such as o-rings, and bearings for example) aren’t stored in close proximity to each other can prevent mix-ups and wasted time.

Optimised warehousing

Challenges to reducing TCO

Having established that it’s possible to reduce TCO and make cost savings across your business, there are many challenges you may face in a bid to achieve these:

- People are incredibly reluctant to change – it’s human nature. And it’s even harder to convince people when it’s not always obvious what the immediate benefits are. Financial gains are not always tangible. Furthermore, implementing change itself costs money and not everyone would consider change worth the apparent hassle that can come with it.

- Accepting the status quo is a big problem for TCO reduction. For example, in one case at a dairy plant, personnel had the radio on really loudly. It became apparent that this was to drown out the noise of the conveyor. No one stopped to think why the conveyor was noisy and whether it should be fixed. On closer inspection, it was evident that the conveyor’s bearings were not running efficiently, causing the motor to work harder than usual and expend extra energy, which could otherwise be saved. But that was just the way it was!

- Streamlining and automating processes frees up staff time and savings on staff hours can be calculated. However, these personnel are still employees with rights. You can’t simply reduce their workload and you will still have salaries to pay. Instead, consider how their time can be best spent to ensure they are doing jobs they are most skilled for.

- Another challenge in calculating TCO is identifying the right data to use, and getting access to that data and to the right people who would hold this information. A misalignment of goals between the various business functions also doesn’t help. There is typically a disparity between how procurement teams purchase supplies and how those on the shop floor need to operate, which doesn’t make it easy.

One way to influence colleagues is by building a business case that demonstrates the opportunities for TCO reduction. Being able to show what the resulting positive financial impact would be is a powerful tool.

Building a business case

As we can see, there is much more than meets the eye when it comes to considering TCO. It is not simply just a case of ensuring a product has minimal maintenance or a long life, but also incorporates all costs associated with purchasing and stocking.

Building a business case of why it is important to consider TCO can help you achieve internal buy-in and prove its value. A good place to start is by looking at the current situation and way of operation, and all the costs associated with the product.

You could begin with making a checklist and calculating the TCO for various scenarios and set ups. Alternatively, you can bring in experts who will help you identify exactly where savings can be made and make it a much easier process, ensuring that you have considered all the opportunities.

For example, if you change a motor for a more energy efficient one, you do not simply benefit from a one-off reduced energy cost, there is an ongoing benefit in time as you will realise the savings year after year.

Consider too that calculating and improving the TCO has much wider implications for the business and that the benefits can be realised throughout the supply chain. For example, achieving a 10% reduction in downtime, not only means you can operate more efficiently and realise cost savings, but also think about what it means to your customer? Are you in a position to be more competitive in the market?

Conclusion

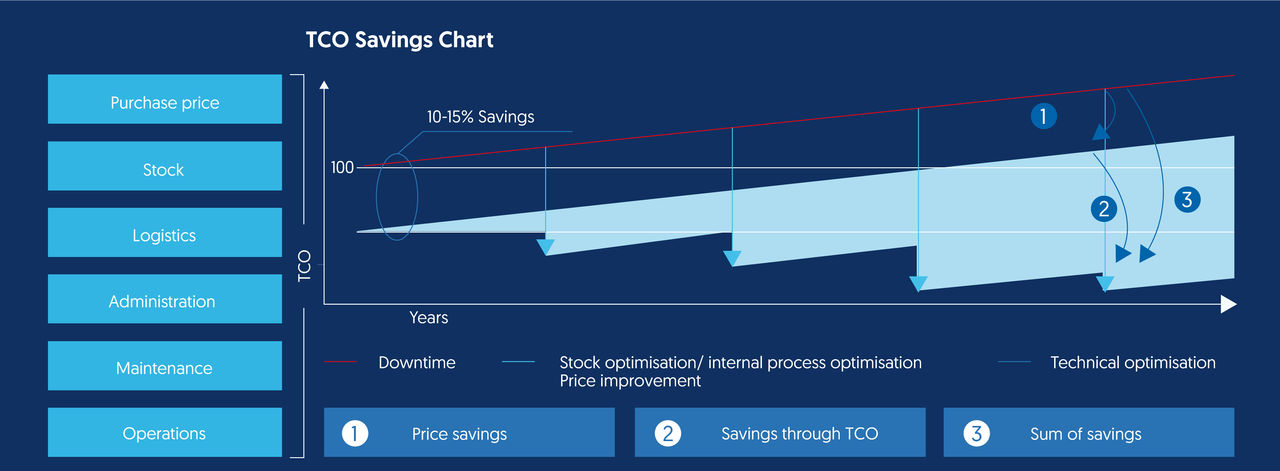

By shifting the focus from just the purchase price to the complete TCO, annual savings of between 10% and 15% of the total purchase value of the products can be made. In figure 1 you can see that during a product lifetime, the TCO decreases thanks to implementing improvements in your processes

TCO saving chart

Our engineers can help you navigate your TCO reduction journey easily, by identifying areas where savings can be made, to calculating the savings that can be achieved.

Subscribe to our newsletter:

For the latest industry news and updates.