Chemical Resistance Guide

For more details about chemical resistance, please check our Rubber Chemical Resistance Guide.

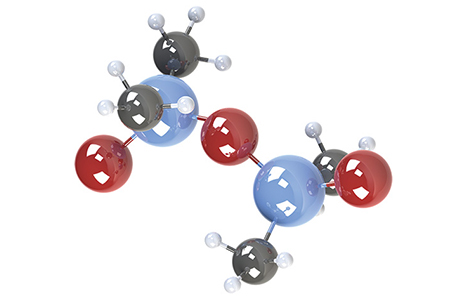

VMQ (often referred to as silicone) is an elastomeric material made from silicone, oxygen, hydrogen, and carbon. VMQ stands for Vinyl Methyl Quartz but is also described as MVQ. The names VMQ, MVQ, and silicone, all refer to the same material. There are also special types such as FVMQ (fluoro-silicone) and PVMQ (phenyl silicone).

Silicone is famous for in-home sealing applications, such as silicone kits for kitchens, bathrooms, and windows. That is mostly room temperature vulcanized (RTV) silicone. The VMQ materials at ERIKS Sealing & Polymer are high-temperature vulcanized (HTV) and Liquid Silicone Rubber (LSR).

Silicones are known for their extreme high-temperature resistance, low-temperature flexibility and good resistance to UV, oxygen, and ozone. A significant advantage of silicones is that they can be filled easily with different additives to create special silicone types with good electrical or thermal conductivity, flame resistance, etc.

Overall, VMQ mechanical strength is poor compared to carbon rubber (EPDM, NBR, FKM, etc.), resulting in lower tensile strength, lower tear resistance, and lower abrasion resistance. Additionally, the relatively high friction makes VMQ unsuitable for use in dynamic applications unless you have no other choice.

For seals, the typical use of silicone is:

Many silicone compounds have a higher mould shrinkage compared to many carbon elastomers (EPDM, NBR, FKM, etc.). Therefore, production moulds for silicone products are often different compared to other elastomer materials.

For more details about chemical resistance, please check our Rubber Chemical Resistance Guide.

To guarantee the best quality for custom products, we work with Six Sigma engineering methods, Finite Element Analysis (FEA) simulations and special development processes.

Want to speak directly with one of our employees or specialist? Don’t wait and get in touch

Get in contact with us. Please fill in our online form and we will contact you as soon as possible.

Found a product, service or solution but you need to first discuss this with your team? We help you to collect and send all the information to your team.