Chemical Resistance Guide

For more details about chemical resistance, please check our Rubber Chemical Resistance Guide.

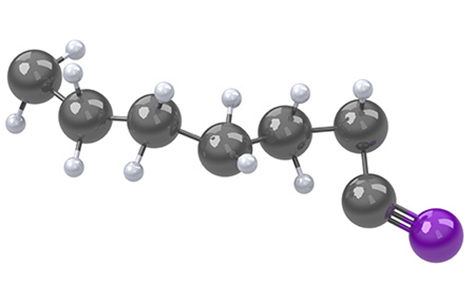

Hydrogenated Nitrile Rubber, abbreviated as HNBR, has been developed to meet higher temperatures than standard NBR while retaining resistance to mineral-based oils. Additionally, HNBR offers outstanding resistance to glycol-based coolants, hot water, and ozone.

HNBR is obtained by hydrogenating the nitrile copolymer. It fills the gap left between NBR, EPDM and FKM elastomers where high-temperature conditions demand high tensile strength along with superior resistance to motor oils, sour gas, amine/oil mixtures, oxidized fuels, and lubricating oils.

The characteristics of HNBR depend on the acrylonitrile (ACN) content and the extent of hydrogenation applied to the butadiene copolymer. An increase in ACN content enhances the elastomer's resistance to hydrocarbon oils, albeit at the expense of reduced flexibility in low-temperature environments.

HNBR can either be cured with sulphur or peroxide, depending upon which properties are the most important.

For more details about chemical resistance, please check our Rubber Chemical Resistance Guide.

To guarantee the best quality for custom products, we work with Six Sigma engineering methods, Finite Element Analysis (FEA) simulations and special development processes.

Want to speak directly with one of our employees or specialist? Don’t wait and get in touch

Get in contact with us. Please fill in our online form and we will contact you as soon as possible.

Found a product, service or solution but you need to first discuss this with your team? We help you to collect and send all the information to your team.