Chemical Resistance Guide

For more details about chemical resistance, please check our Rubber Chemical Resistance Guide.

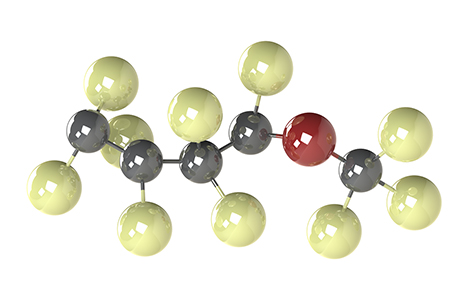

FFKM, also known as perfluorelastomer (FFPM), is a family of elastomer materials with a fully fluorinated polymer backbone, resulting in fluorine content of over 71%. As a result, they are recognized as elastomers that offer the highest level of chemical resistance. Since FFKM's chemical resistance is second to none, it displays good performance in a broad variety of harsh environments: hot amines, steam, solvents, hydrocarbons, etc.

Depending on its specific type, FFKM offers the highest temperature resistance available for rubber materials. Particularly, its combination of excellent high temperature and chemical resistance positions FFKM solely on the top of the elastomer world.

Traditionally, FFKM polymers were known for their limited resistance to low temperatures. However, advancements in polymer chemistry have led to the development of FFKM grades that are capable of effective sealing at temperatures as low as -40°C.

FFKMs come in different kinds, and the main difference between them is the type of curing agents they use.

Common FFKM Types

Curing Agent

High temperature resistance

Specific information

Peroxide

240oC

Broad chemical resistance

Triazinic

327oC

High temperature, excellent mechanical properties. Reduced chemical and steam resistance

Modified Triazinic

275oC

Broad chemical resistance, excellent mechanical properties.

Modified Peroxide

325oC

High temperature resistance, excellent mechanical properties, reduced amine and base resistance

A famous FFKM brand name is Kalrez® from DuPont, with whom ERIKS partners in many countries. Additionally, ERIKS offers its own line of FFKM materials under the brand XTR-Fluor, which is marketed in the UK.

FFKMs are the most expensive rubber materials, and therefore a purely item-to-item price comparison with other rubber materials is not useful. In some cases FFKMs are the only realistic option, but in other cases the use of FFKM may provide greater benefits in Total Cost of Ownership (TCO) via less machine or factory down-time, less repairs and inspections for greater productivity and yield, and better equipment/machine performance.

FFKMs are used in different industries such as petrochemical, food, pharma, oil&gas and semicon. For clean high tech applications in semicon, electronics or optics, ERIKS has a special SCVBR® program.

For more details about chemical resistance, please check our Rubber Chemical Resistance Guide.

To guarantee the best quality for custom products, we work with Six Sigma engineering methods, Finite Element Analysis (FEA) simulations and special development processes.

Want to speak directly with one of our employees or specialist? Don’t wait and get in touch

Get in contact with us. Please fill in our online form and we will contact you as soon as possible.

Found a product, service or solution but you need to first discuss this with your team? We help you to collect and send all the information to your team.