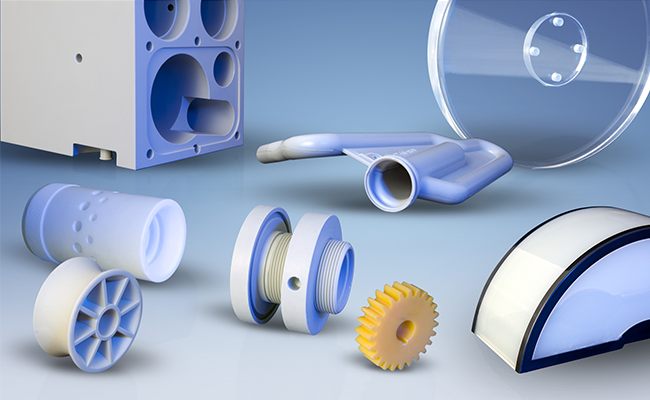

Polycarbonate (PC) is a durable, impact-resistant synthetic material ideal for safety glazing and protective shields in industrial settings. It offers exceptional clarity and ductility and is up to 250 times stronger than equivalent glass, ensuring high safety and performance. PC is flexible, withstands temperature changes (up to 135°C briefly, 115°C over time), but is sensitive to chemicals and scratches, requiring careful handling.

ERIKS' branded Epraform PC includes options for scratch resistance, UV protection, and anti-static properties, enhancing its versatility in various applications.