A marathon in the lab

Smart test setup for unique running sensor

Collaboration ERIKS & Dynteq

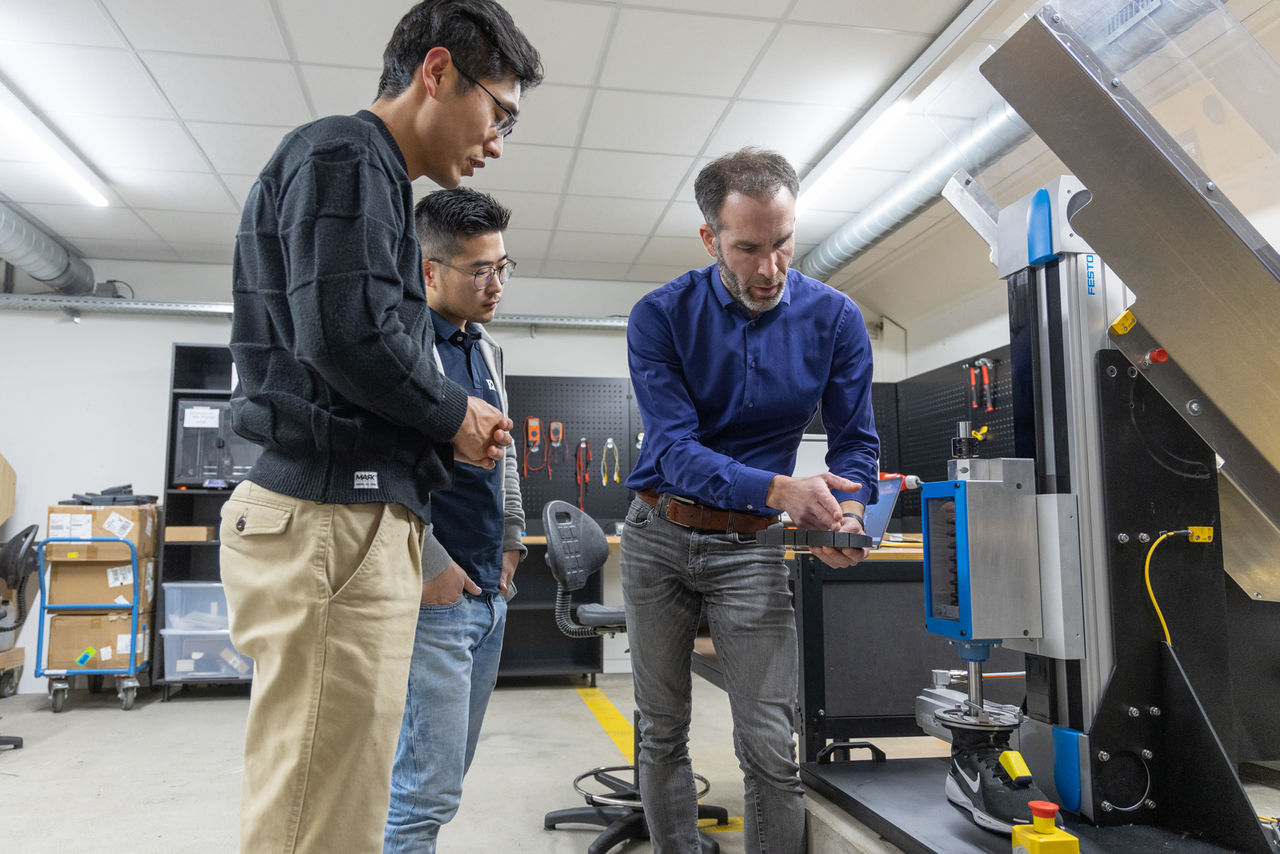

The start-up WearM.AI, a spin‑off from the University of Twente in the Netherlands, is developing a sensor for analyzing running movements. ERIKS supported Dynteq with the co‑engineering and fine‑tuning of a setup to test the sensor’s lifespan and robustness. By choosing Festo components, the software costs could be kept within the available budget.

Huawei Wang, researcher and founder of WearM.AI, knows from personal experience how difficult it can be to find the cause and solution for running injuries. “I’ve tried everything: wearing different shoes, adjusting my running technique, and visiting physiotherapists. The human body is complex. I wanted to develop something that tracks runners and records their movements. By analyzing data on foot landing and the motion of the hips, knees, and arms, we can provide targeted advice. A colleague decided to join me on this journey, and within two years we have grown into a team of seven people.”

A New Way to Understand Running

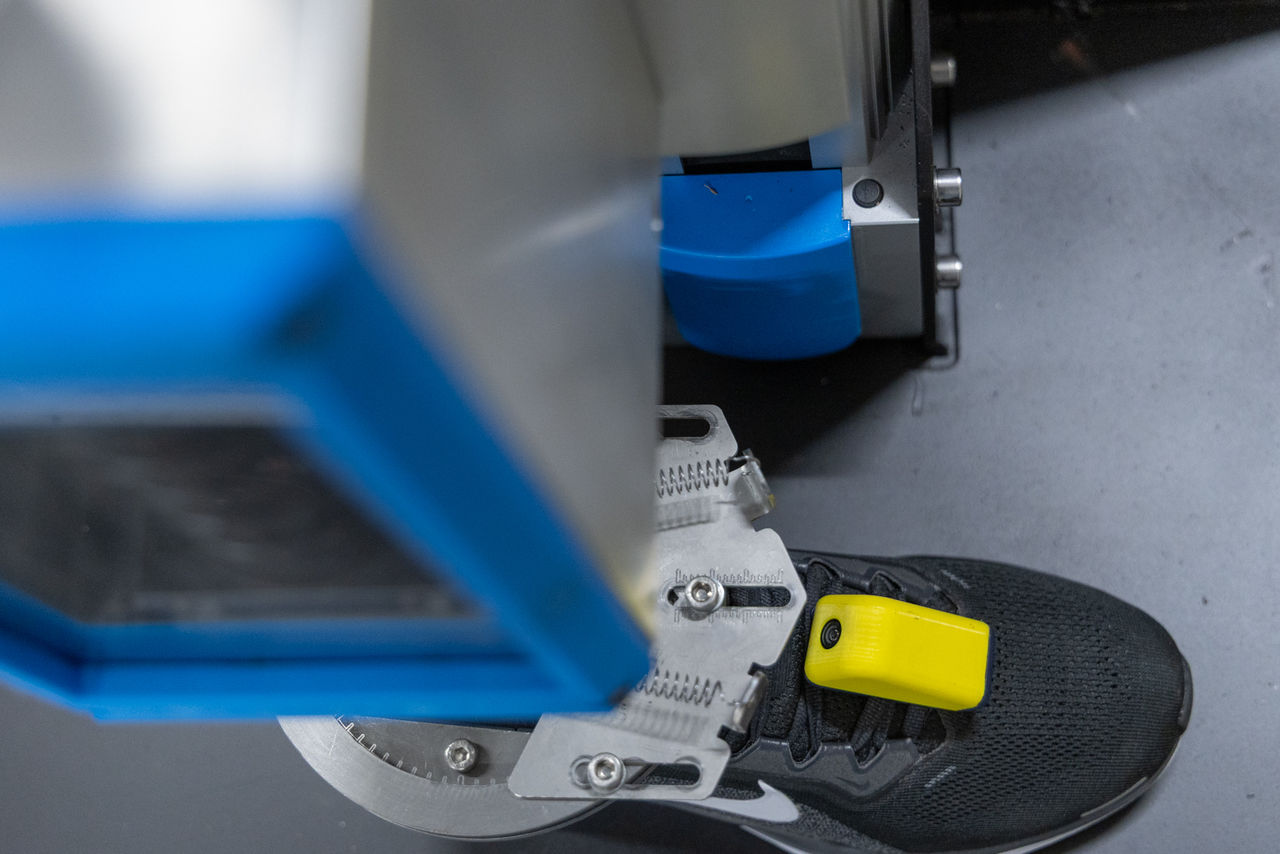

WearM.AI is developing a revolutionary sensor that helps runners understand their movement like never before. Instead of using multiple sensors across the body, this system uses just two small devices attached to your shoes. Combined with smart cameras and cloud technology, it can create a complete 3D picture of your running motion and even calculate forces on your joints. This innovation has already won several awards and could change how athletes train and prevent injuries.

The challenge

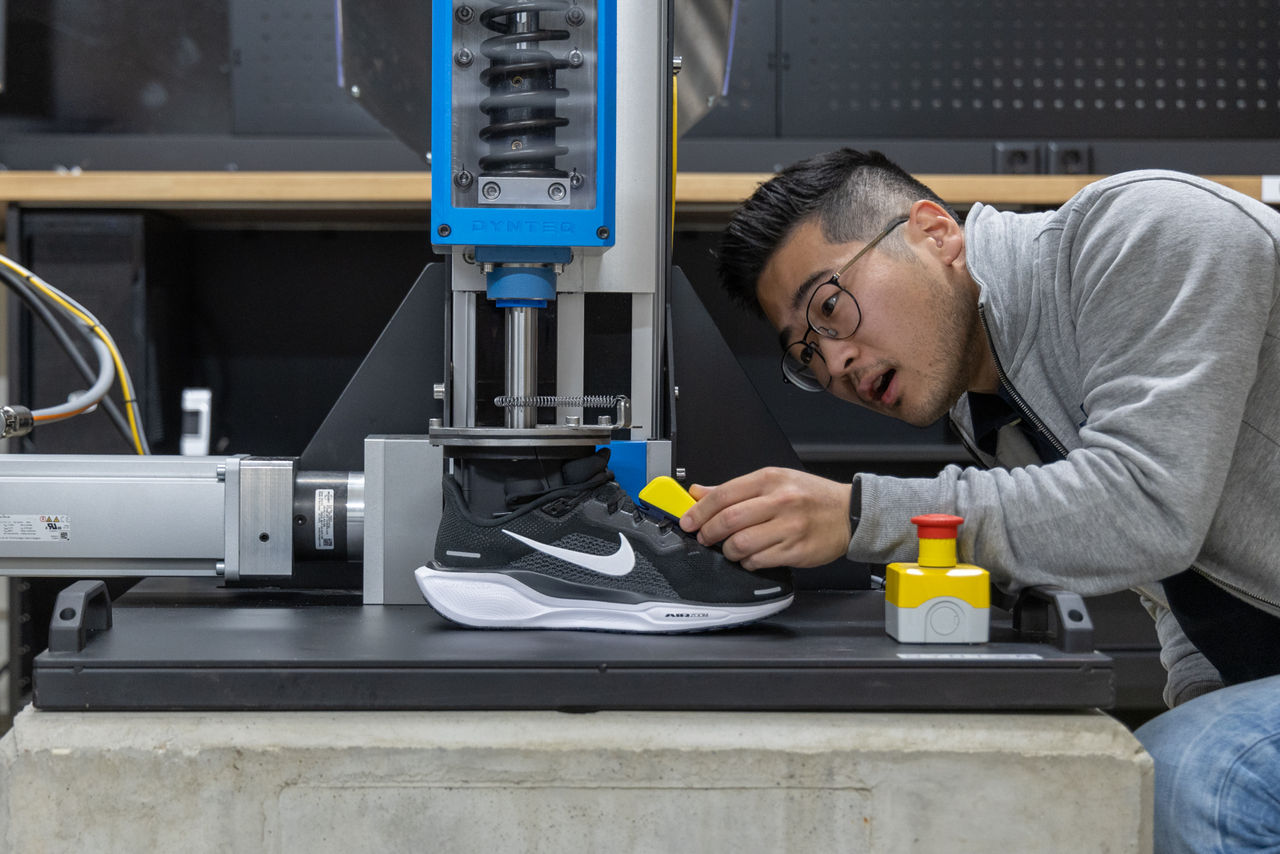

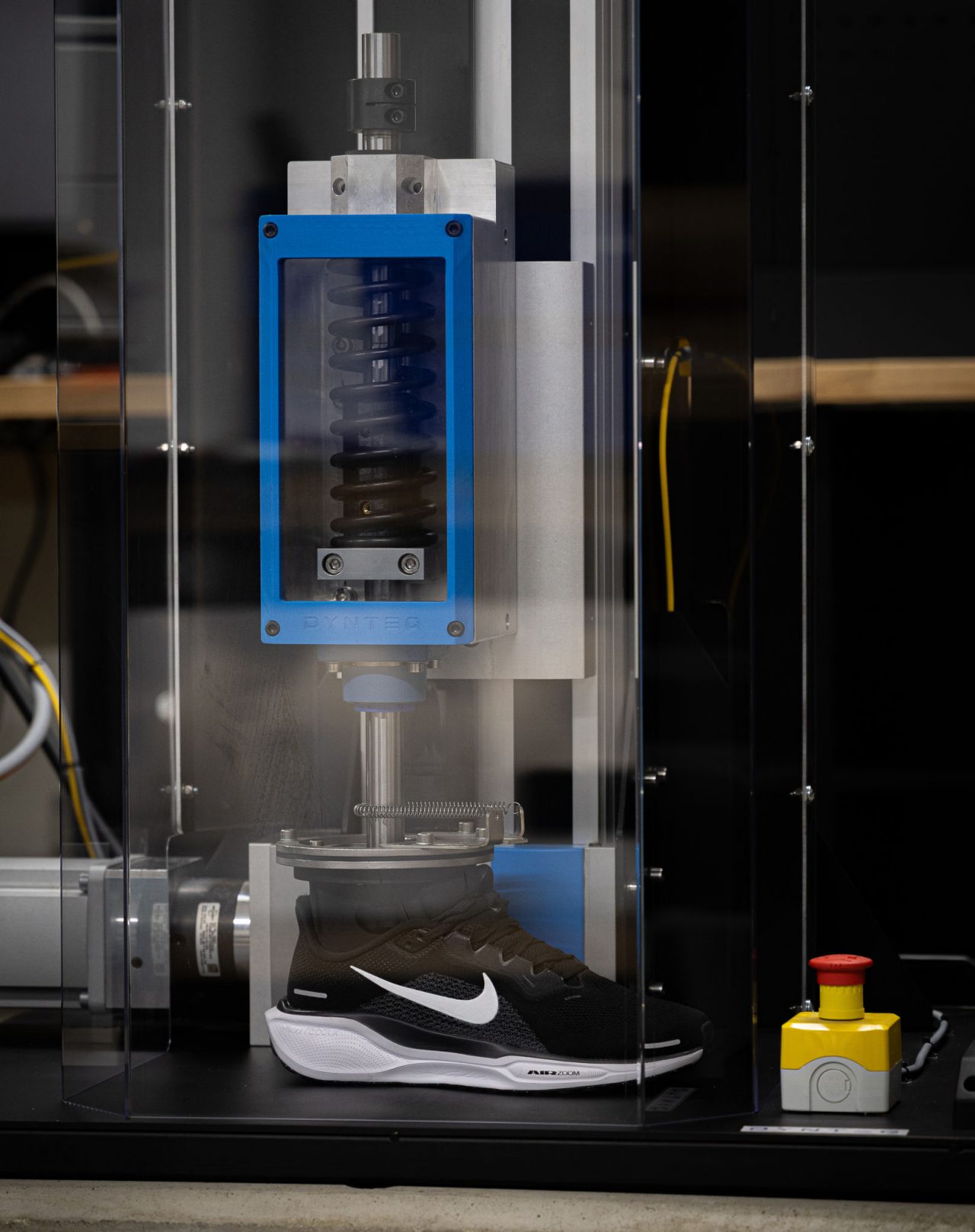

Before this technology can hit the market, it needs to prove it can withstand real-world conditions. That means testing how durable and reliable the sensors are over thousands of steps, under heavy impact, and in different environments.

The solution

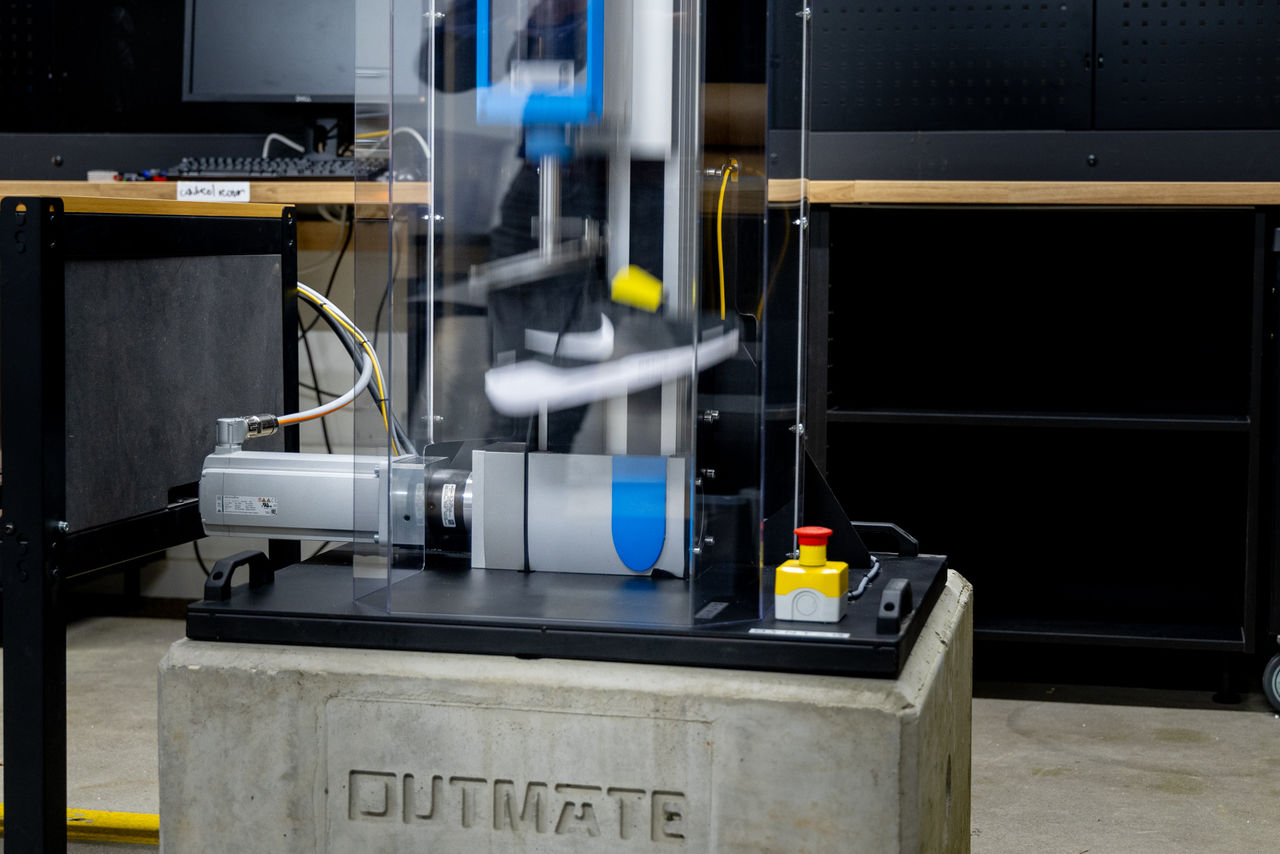

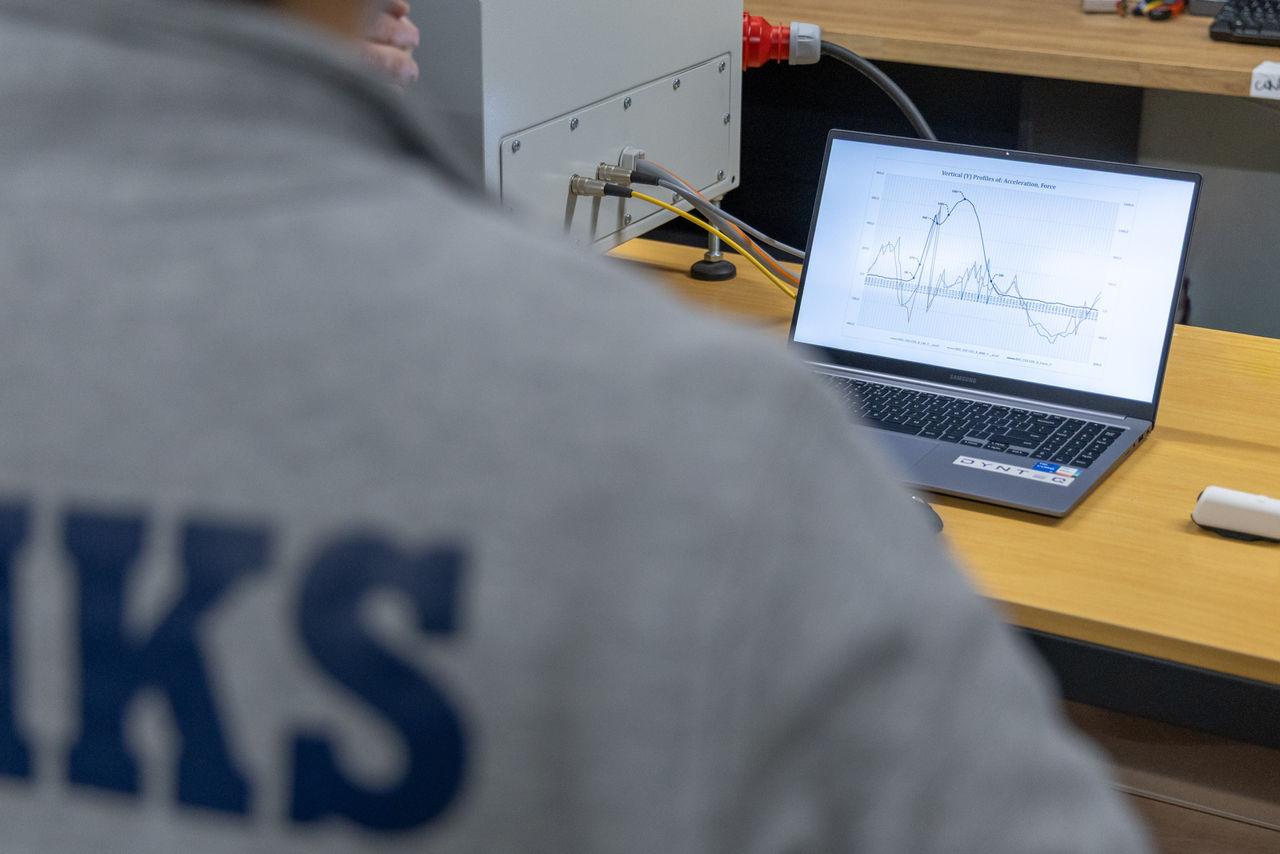

To make this possible, WearM.AI partnered with Dynteq and ERIKS to build a unique test setup. This machine simulates the motion and impact of running, allowing the sensors to be tested as if they were running multiple marathons, without leaving the lab. The goal was simple: create a practical, cost-effective solution that could deliver accurate results and help speed up development.

Working together

Dynteq designed the mechanical setup, while ERIKS provided expertise in selecting components and programming the system. By working closely with Festo, the team created a smart and efficient rig that can be upgraded in the future, to test sensors in different climates for example.

Looking Ahead

The sensor is expected to be ready for production by mid-2026. Once validated, WearM.AI plans to launch an app that acts as a digital coach, giving runners real-time feedback and personalized advice to help prevent injuries. Professional athletes, coaches, and sports organizations are already showing interest in this technology.