In this article

When do you use an X-ring?

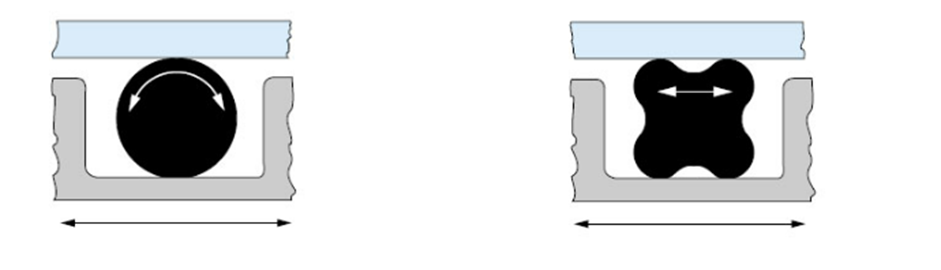

An X-ring, also known as a quad ring, is similar to an O-ring, the primary distinction being its cross-sectional shape. While an O-ring has a round cross-section, an X-ring has an X-shaped cross-section, hence the name. X-rings were developed to serve as enhancements to O-rings under certain conditions. Both X-rings and O-rings are double-acting seals, meaning they can seal in both directions.

Choosing an X-ring over an O-ring can be beneficial in a number of situations, with these advantages applicable in both static and dynamic applications. The X-ring is commonly chosen as a superior alternative to the O-ring for several reasons, such as:

- Prevention of Premature Leakage in Dynamic, Sliding Applications: One of the biggest issues with O-rings in sliding applications (such as piston or rod sealing) is that they have a tendency to twist. This twisting can potentially create a leakage path, leading to premature failure. X-rings, due to their X-shaped cross-section, are less likely to twist, offering enhanced stability and, consequently, better sealing performance.

- Extended Seal Life: X-rings have a lower friction coefficient compared to O-rings, which means less wear and longer service life. This is especially important in dynamic applications where the seal is constantly in motion.

- More Sealing Efficiency: X-rings have four points of contact as opposed to two points in O-rings. This means that X-rings have twice the sealing surface in contact with the part, which makes them more efficient at preventing leaks.

- Resistant to Extrusion and Spiral Failure: X-rings are more resistant to extrusion and spiral failure due to the larger surface area in contact with the hardware. This can be beneficial in high pressure applications.

- More Tolerance to Lubrication Conditions: X-rings can handle a wider range of lubrication conditions, which makes them more versatile in various applications.

X-ring materials

X-rings can in principle be made in most O-ring compounds. However, the standard range focuses mainly on compounds used in dynamic applications in contact with oil:

ERIKS NBR 36624

NBR 36624 is the most common material for applications with hydraulic and lubricating oils. NBR is not ozone- and UV-resistant and can accelerate ageing when exposed to ozone and UV. For example, our standard NBR Compound 36624 has a range of -30C to 120C, in oil it is recommended to go up to 100 degrees maximum.

ERIKS FKM 51414

FKM is commonly called 'Viton', after one of the best-known FKM brand names, Chemours' Viton™. The ISO designation is FKM. ERIKS FKM 51414 is a high-quality fluoroelastomer, black in colour, which is highly resistant to many chemicals, oil, grease and fuels and, due to its high density, can also be used in vacuum applications. There are many different types within the FKM family. The basic types (co-polymers) are not suitable for use in steam applications.

FKM 51414 can withstand much higher temperatures than NBR 36624 and can therefore be a better choice for high-temperature oil, for example. Our FKM 51414 has a temperature range of -20C to 200C.

ERIKS EPDM 55914

Cet EPDM 70 noir assure l'étanchéité aux acides, aux bases, à l'eau chaude et à la vapeur à basse pression. En outre, il est résistant à l'ozone et aux UV. Ce matériau ne convient pas aux applications dans lesquelles des graisses et des huiles minérales et animales sont utilisées. Ce matériau a une plage de température de -55 °C à +130 °C. Si la température de votre application est supérieure à +130 °C, choisissez le composé 55915.

Which X-ring size do I choose?

Choosing the right size X-ring is important for the proper functioning of the seal. For dynamic use, it is recommended to take the thickest possible size of X-ring. A thicker X-ring also compensates for wear phenomena better, the compression set is more favourable, the dynamic sealing ability is also better and can accommodate larger movement gaps better. For static seals, a smaller cross-section can also do well.

Subscribe to our newsletter:

For the latest industry news and updates.