In this article

REACH Compliance: Best Practices for Industrial Manufacturers

In today's rapidly evolving regulatory landscape in the European Union, the importance of integrating REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance into your manufacturing processes cannot be overstated. As an industrial manufacturer, you play a pivotal role in safeguarding our environment and public health by adhering to these stringent standards. This article aims to provide you with valuable insights on establishing REACH-compliant protocols, fostering a culture of responsible chemical management, and enhancing the productivity and efficiency of your operations.

REACH is a European Union legislation, EC 1907/2006, that came into effect on June 1, 2007. It is intended to encourage the use of safer chemicals and to promote the substitution of hazardous substances with safer alternatives. By doing so, REACH helps to protect human health and the environment while promoting innovation and competitiveness in the chemical industry.

The REACH regulation requires a European Chemicals Agency (ECHA) registration of these chemicals when produced, imported, or used above a specific threshold level.

As a company, you must provide information on the properties of the chemicals you produce or import, as well as the risks associated with their use. This information is used to evaluate the risks posed by the chemicals, and to authorize or identify any necessary restrictions on their use.

Restricted Materials

According to annexe XVII from REACH Regulation, restricted materials can be used by everyone, as long as the applicable restrictions are complied with.

Materials subject to authorization

According to annexe XIV from REACH Regulation, materials subject to authorization are only allowed to be produced, imported or used when a permission is granted by the ECHA organization.

Some examples of materials that are or restricted or subject to authorization under REACH include:

CMR substances:

Carcinogenic, mutagenic, or toxic to reproduction (CMR) substances: These are substances that are known or suspected to cause cancer, genetic mutations, or other reproductive problems. Examples include lead, cadmium, and asbestos.

PBT substances:

Persistent, bio-accumulative, and toxic (PBT) substances: These are substances that are highly toxic, do not break down easily in the environment, and accumulate in living organisms. Examples include mercury, some pesticides, and certain flame retardants.

Substances of very high concern (SVHCs)

SVHCs are substances that have been identified as potentially hazardous to human health or the environment, but for which there is not yet enough information to make a definitive determination. SVHCs are listed on the ‘Candidate List of substances of very high concern for Authorization’ and are in fact in a preliminary stage to be listed as to be subject to authorization . Examples include some phthalates, bisphenol A, and certain flame retardants.

The presence of a SVHC substance in a material above a specific threshold level requires to be communicated within the supply chain and appropriate safety information needs to be shared.

For instance, for products containing SVHCs in concentrations exceeding 0.1% by weight, a SCIP (Substances of Concern In articles as such or in complex objects (Products)) registration is mandatory. The SCIP database is part of the Waste Framework Directive (2008/98/EC) and aims to provide transparency and traceability for SVHCs. Manufacturers, importers, and distributors must submit the relevant information to the ECHA and comply with SCIP requirements to maintain market access and avoid penalties.

Additional requirements

In addition to these specific materials, REACH also includes general requirements for the safe use of chemicals, including requirements for labeling, packaging, and the provision of safety data sheets.

Companies that manufacture, import, or use chemicals in the EU must comply with these requirements and take steps to minimize the risks associated with their use.

REACH vs. RoHS

Both REACH and RoHS aim to protect human health and the environment from the risks posed by chemicals, yet they have different scopes and focus on different aspects of chemical safety.

REACH

is a comprehensive regulation that covers all chemicals used in the EU, whether they are used in consumer products or in industrial processes. REACH also includes provisions for the authorization and restriction of certain hazardous chemicals.

RoHS

(Reduction of Hazardous Substances), on the other hand, is a more focused regulation that specifically restricts the use of certain hazardous substances in electrical and electronic equipment (EEE). RoHS applies to all EEE sold in the EU, regardless of where they were manufactured.

RoHS 2, formally known as Directive 2015/863, officially came into effect on July 22, 2019, expanding upon the previous regulation. This updated directive increased the total number of hazardous materials from six to ten. Consequently, under the new guidelines, manufacturers now need to conduct mandatory testing for these ten substances to ensure compliance.

A key difference between REACH and RoHS is that REACH is primarily concerned with the risks posed by chemicals themselves, while RoHS focuses on the risks posed by the products that contain these chemicals. In other words, REACH aims to ensure that chemicals are safe for human health and the environment, while RoHS aims to ensure that products containing these chemicals are safe for consumers to use.

The Role of ECHA

ECHA stands for European Chemicals Agency, responsible for implementing the REACH regulation, as well as the CLP (Classification, Labeling and Packaging) regulation.

ECHA is based in Helsinki, Finland, and was established in 2007 with the goal of improving the protection of human health and the environment from the risks posed by chemicals.

The agency is responsible for a number of tasks, including:

- Registering chemicals produced or imported into the EU in quantities of one ton or more per year.

- Evaluating the safety of chemicals and their potential risks to human health and the environment.

- Authorizing the use of certain hazardous chemicals that are subject to authorization requirements.

- Restricting the use of hazardous chemicals that pose a significant risk to human health or the environment.

- Providing guidance and support to companies on how to comply with the REACH and CLP regulations.

- Promoting the development and use of alternative methods to animal testing.

- Maintaining a central database of information on chemicals that are produced, imported, or used in the EU.

ECHA plays a crucial role in ensuring that the chemicals used in the EU are safe for human health and the environment, and in promoting the sustainable use of chemicals.

Protocols for REACH Compliance

As a company that manufactures, imports, or uses chemicals in the EU, you must take the necessary measures to ensure your processes are REACH compliant.

A rigorous compliance protocol includes the following steps:

- Identify all substances the company produces, imports or uses and determine whether they are subject to registration, authorization or restriction under the REACH regulation.

For substances subject to registration:

- Submit a registration dossier to ECHA that includes information on the substance's specifications, uses, hazards, and risk management measures.

- Share relevant data with other registrants to avoid unnecessary duplicate testing. This includes data on the substance's properties, toxic effects and environmental impact. Not only does this help to reduce costs and improve efficiency, but it also helps to avoid unnecessary animal testing. Data sharing also promotes the development of safer and more sustainable chemical substances and products.

ECHA maintains a central database of information on registered substances, which includes data shared between registrants. This database, known as the REACH Registration Database, is accessible to the public.

- Create and Maintain Safety data sheets (SDS) for each substance that is produced, imported or used. It is an important tool for ensuring the safe use of chemicals.

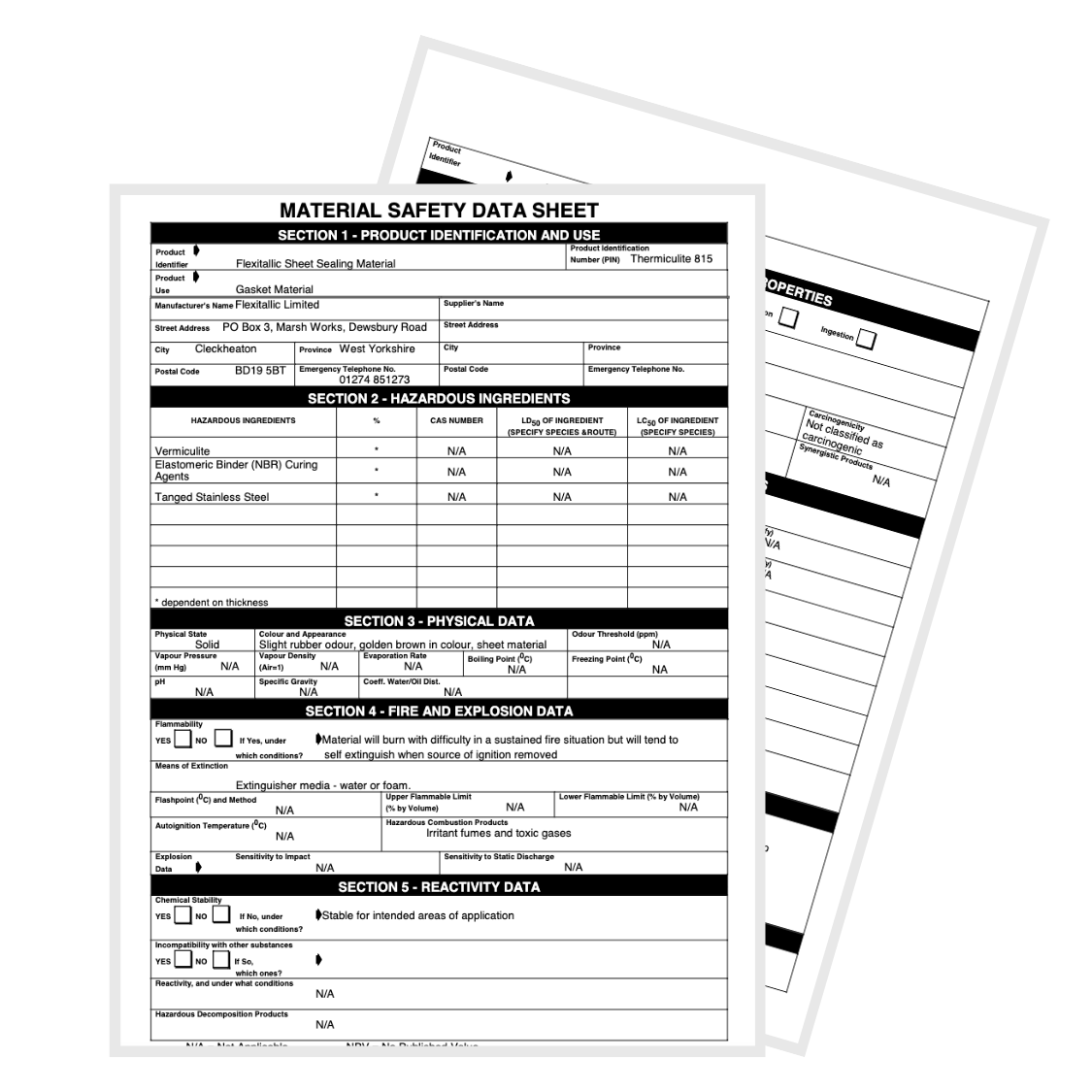

Example data sheet

The SDS typically includes information on the substance's physical and chemical properties, hazards and risks, safe handling and storage procedures and regulatory information. It also provides guidance on appropriate personal protective equipment (PPE) and first aid measures in case of exposure or accidents.

Roles & Responsibilities

The responsibility for REACH compliance within a company falls on different parties, depending on their role in the supply chain and their specific obligations under the REACH regulation. The main responsible parties are:

Manufacturers:

Manufacturers of chemical substances or mixtures are responsible for ensuring that their products are registered with ECHA, and that the necessary data and information is provided to support their safe use.

Importers:

Importers of chemical substances or mixtures from outside the EU are responsible for ensuring that their products are registered with ECHA and that they comply with all relevant REACH requirements.

Downstream users:

Downstream users of chemical substances or mixtures are responsible for ensuring that they comply with all applicable requirements under REACH, such as restrictions and authorization requirements. They are also responsible for ensuring that they use the substances safely and provide any necessary information to their customers and end users.

Only Representatives:

Only Representatives (ORs) act on behalf of non-EU manufacturers to fulfill their REACH obligations. ORs are responsible for ensuring that the substances they represent are registered with ECHA, and that the necessary data and information is provided to support their safe use.

Distributors:

Distributors of chemical substances or mixtures are responsible for ensuring that the substances they distribute are properly labeled and that they comply with all applicable REACH requirements.

It is your responsibility as a company to ensure that you are in compliance with REACH, and to establish appropriate processes and systems to ensure compliance throughout your supply chain. This may involve appointing specific individuals or departments to manage REACH compliance and ensure that the necessary procedures and protocols are in place.

ERIKS' Commitment to Compliance

Here is a Checklist that can Help you Work in a Reach-Compliant Way:

- Identify your obligations: Determine whether your company has any obligations under the REACH regulation, such as registration, authorization, or restriction requirements.

- Inventory your substances: Identify the chemical substances used in your company's products and operations, including substances in mixtures.

- Check the status of your substances: Check whether your substances are registered with ECHA, and whether they are subject to any restrictions or authorization requirements.

- Determine the quantities of your substances: Determine the quantities of your substances that are manufactured, imported, or used within the EU, as this can affect your REACH obligations.

- Conduct risk assessments: Conduct risk assessments of your products and processes to identify potential hazards and risks associated with chemical substances and take appropriate measures to mitigate these risks.

- Communicate information: Communicate information on the safe handling and use of your products and substances to downstream users, including through Safety Data Sheets (SDS) that comply with REACH requirements.

- Collaborate with your supply chain: Work closely with your suppliers to ensure that the products you source comply with REACH requirements, including restrictions on the use of certain hazardous substances.

- Maintain accurate records: Keep accurate records of your substance inventories, registrations, and other relevant information to demonstrate compliance with REACH.

- Monitor regulatory developments: Stay up to date with regulatory developments and changes to the REACH regulation – adjust your practices and procedures accordingly.

Environmental Responsibility

It is important to note that REACH compliance is an ongoing process, and as a company you must continually monitor your use of chemicals and adjust your practices as necessary to guarantee continued compliance with the regulation.

In this way, you ensure the responsible management of chemicals throughout their lifecycle, from sourcing to end-of-life disposal. This not only mitigates the potential risks posed to human health and the environment, but also fosters a culture of transparency and accountability within the industry. The systematic evaluation and communication of chemical hazards enables you to identify and implement safer alternatives, optimize the use of resources and minimize waste. Thus, through proactive compliance efforts, you can greatly impact the industry's long-term sustainability in a growing eco-conscious market.

Sources:

https://echa.europa.eu/nl/home

https://environment.ec.europa.eu/topics/chemicals/reach-regulation_en

https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02006R1907-20221217

https://environment.ec.europa.eu/strategy/chemicals-strategy_en

Article created in consultation with:

- Harrie Vangangelt, COE Quality Compliance Manager Sealing & Polymer

- Ron Ruis, HSEQ Professional Quality & Environment

Subscribe to our newsletter:

For the latest industry news and updates.