In this article

Determining the right o-ring dimensions for your application

Inside diameter, cord thickness, standards... and then there is matching the groove dimensions. It is important to carefully determine the O-ring dimensions. This will prevent leaks and malfunctioning or non-functioning of your machine or product. You should therefore know what to look out for and how to determine the size so that you choose the right O-ring for an optimal seal in your application.

New machine or a repair?

An O-ring that is used as a seal is always mounted in a groove. That groove must meet certain conditions in terms of dimension and finish, so that the O-ring functions optimally.

If you are developing a new machine or a new product where an O-ring must be used, you usually have various options for determining the correct groove dimensions. Here, you can read more about groove design and also find a link to our O-ring and groove calculator.

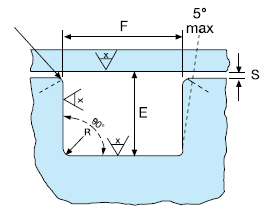

However, if you are making a repair, you usually can't adjust anything about the groove dimensions. That is a given. You will then look for a suitable O-ring for an existing groove. In that case, you should first check the existing groove dimension on a drawing or measure the groove (see figure below for explanation). The inner diameter of the groove, the groove width (F), but also the distance (E) is important. So make sure you don't just take the groove depth, but add the groove depth and any gap (S) when in its assembled state. This cannot always be measured and therefore has to be calculated sometimes.

Without knowledge of the groove dimensions, it is difficult, risky or sometimes impossible to determine the correct O-ring size. It is not recommended to determine an O-ring size by measuring a used O-ring.

What is an ideal O-ring size?

The ideal inner diameter and cord thickness depend on the application:

a) Inner diameter

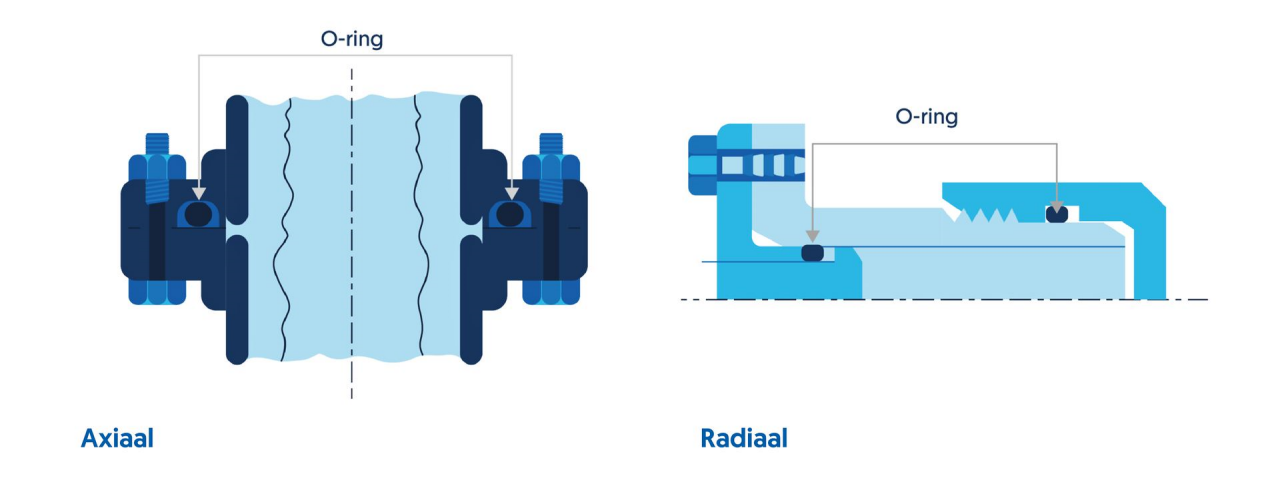

- Axial seal

- Internal system pressure: the O-ring is best placed against the outer diameter of the groove

- External system pressure: the O-ring is best placed against the inner diameter of the groove

- Radial seal

- O-ring in the piston: the O-ring is best stretched around the groove in the piston

- O-ring in the cylinder: the O-ring is best pressed against the outer diameter of the cylinder groove

The O-ring cross-section (refer to round, black shapes) is pressed radially into the groove between the inside (interior diameter or ID) and the outside (outside diameter or OD).

The O-ring cross-section (refer to round, black shapes) is pressed axially into the groove.

The O-ring cross-section (refer to round, black shapes) is pressed radially into the groove between the inside (interior diameter or ID) and the outside (outside diameter or OD).

b) Cord thickness

- Static application: 15 to 25% compression in mounted condition. In vacuum applications, compression can be even higher. Compressing at more than 25% does create additional stress for an O-ring. This can lead to premature damage.

- Dynamic application: 8 to 16% in dynamic applications. Due to friction and wear, smaller cross-sections can be compressed by up to 20%.

The cross-sectional area of the rubber O-ring should be at least 15% smaller than the cross-sectional area of the groove. This is necessary because rubber material cannot be compressed and therefore needs free space when compressed. If this margin is smaller, the risk of damage to the O-ring increases.

Useful tip to bear in mind

When looking for the appropriate O-ring size, it is useful to bear in mind that when assembled, you may stretch the diameter of an O-ring by up to 5% or compress by up to 3%, depending on the application.

- Static applications: stretch the diameter by up to 5% and compress by up to 3%.

- Dynamic applications: stretch a piston seal by up to 5% and compress a rod seal by up to 3%

Example: Based on your groove dimension in a static application, you are looking for an O-ring with 308 mm inner diameter and 5 mm cord thickness. However, you cannot find a 308 x 5 mm O-ring, or it is not readily available. Since it is possible to stretch the O-ring diameter by up to 5% and compress it by up to 3%, you can choose an alternative size: 305 x 5 mm (with only 1% stretch), or 310 x 5 mm (with only 0.6% compression).

O-ring sizing standards

There are many international O-ring size standards, which are often used interchangeably. Choosing an O-ring size from an existing standard is convenient, as you are more likely to have it available as standard. There is also an infinite choice of metric sizes, and you can have O-rings customised in every possible size. These are the most common O-ring standards used internationally:

AS 568 / ISO 3601-1 / DIN 3771 / BS 1806 / BS 4518 / French R / JIS B 2401

AS 568 (also AS 568-A)

AS stands for 'Aerospace Standard' and is often described as 'American Standard' because the US Society of Automotive Engineers (SAE) established the AS568. AS 568, or more specifically AS 568-A, is probably the most widely used standard for O-ring sizes worldwide and is quite recognisable because of the O-ring thicknesses such as 1.78mm, 2.62mm, 3.53mm, 5.33mm, 6.99mm.

View the O-ring size chart of the AS 568 standard

ISO 3601-1

ISO has adopted the dimensions from AS568 in the ISO3601 standard. The standard consists of 4 sections. Section 1 (ISO 3601-1) describes the sizes. The differences from AS568 are, for example, in Section 3 (ISO 3601-3) and deal with tolerance and surface quality.

View the O-ring size chart of the AS 3601 standard

DIN 3771

DIN stands for ‘Deutsches Institut für Normung’. The DIN 3771 is an old standard that is less commonly specified but can often be found on older drawings. The O-ring sizes can still be frequently encountered, even outside Germany. Unlike many other O-ring standards, DIN 3771 does not use any additional numbering or code per size.

View the O-ring size chart of the DIN 3771 standard

BS 1806 and BS 4518

BS stands for ‘British Standard’. There are two BS standards for O-ring sizes: BS 1806 and BS 4518 O-ring sizes according to the BS 1806 standard are largely in line with ISO 3601-1. The BS 4518 standard is mainly used within the UK.

View the O-ring size chart of the BS 1806 standard

View the O-ring size chart of the BS 4518 standard

French R

The French R standard overlaps with ISO3601 and AS568, but also has some typical dimensions within its range. The type numbering is identified by the R, such as R12

View the O-ring size chart of the French R standard

JIS B 2401

The JIS standard stands for Japanese Industrial Standard, in which B 2401 is the Japanese O-ring standard. The O-ring sizes are identified by the addition of the letters P, G, S and V which are designated for different applications: P (dynamic), G (static), S (special) and V (vacuum)

View the O-ring size chart of the Japanese JIS standard

Metric sizes (non-standardised)

Metric sizes are not standardised to the size itself. They are usually rounded off to millimetre dimensions or defined to half-millimetre accuracy.

View the O-ring size chart of a wide range of metric sizes

Validate whether the chosen O-ring size is appropriate for your application

Do you want to check if the combination of O-ring size and groove dimensions are properly matched? A helpful tool to check this is our O-ring calculator. Keep the groove dimension on the design drawing close at hand when using this.

O-ring customisation

If, based on all the above information, you still cannot find a suitable O-ring size, then customisation is probably the only solution. This is an option even for a few pieces. This is not a cheap solution, but in certain situations it may be the only or best solution.

There are 3 production methods:

- Moulded: this sometimes involves mould costs

- Turning (machining)

- Vulc-O-ring®: this is an O-ring made of precision cord, which is hot vulcanised. This means the Vulc-O-ring® is not cold glued with superglue or any other type of adhesive, but the ends are vulcanised together in a heated mould with rubber compound. This creates a qualitatively very strong, yet flexible connection. This can only be used in static applications.

All solutions are available upon request.

Help in determining the O-ring size

Still unsure about the right O-ring dimensions for your seal? Or do you have another question about the O-ring in your application? Our product specialist would be happy to take a look and advise you on how to proceed.

Subscribe to our newsletter:

For the latest industry news and updates.