Ergonomic solutions help prevent musculoskeletal disorders

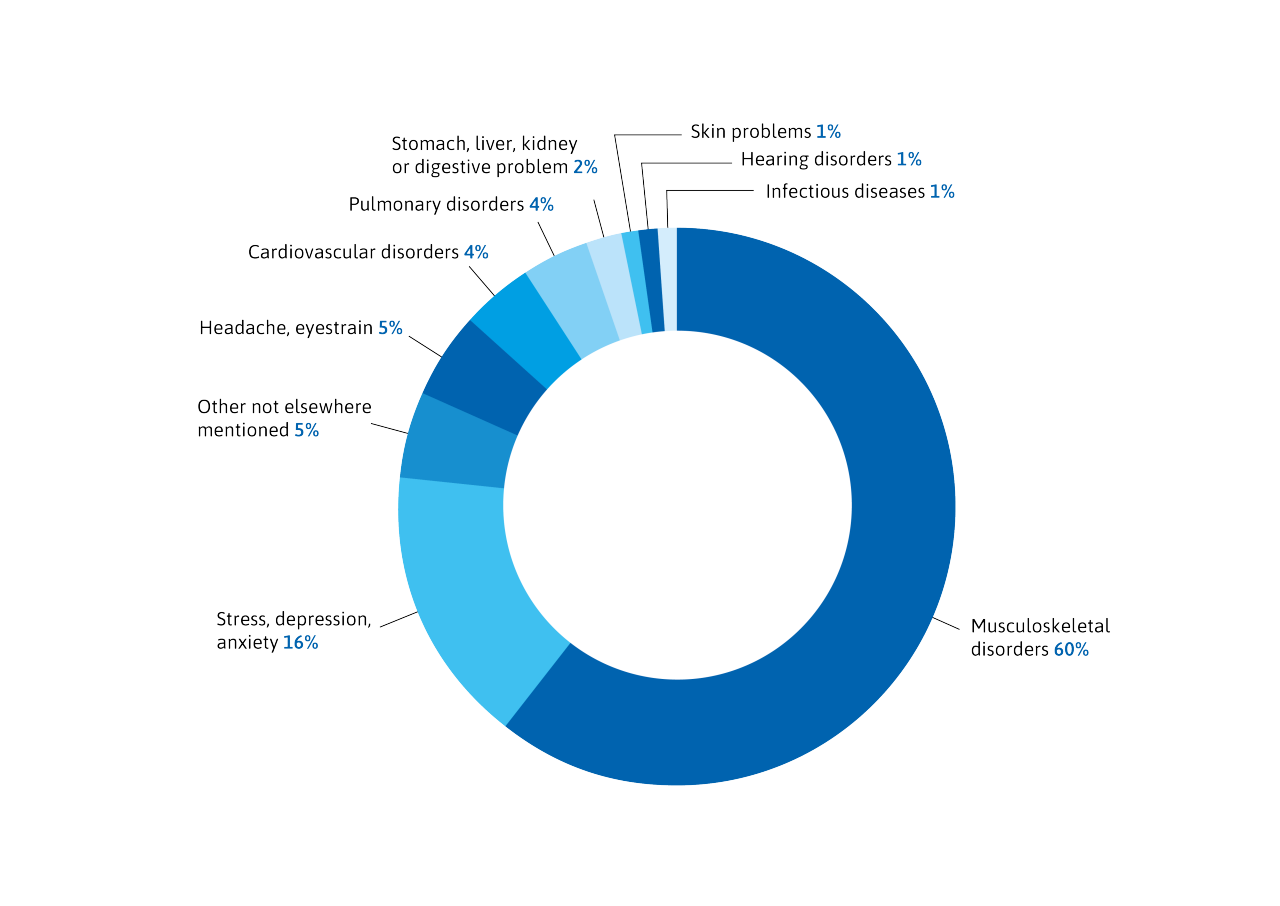

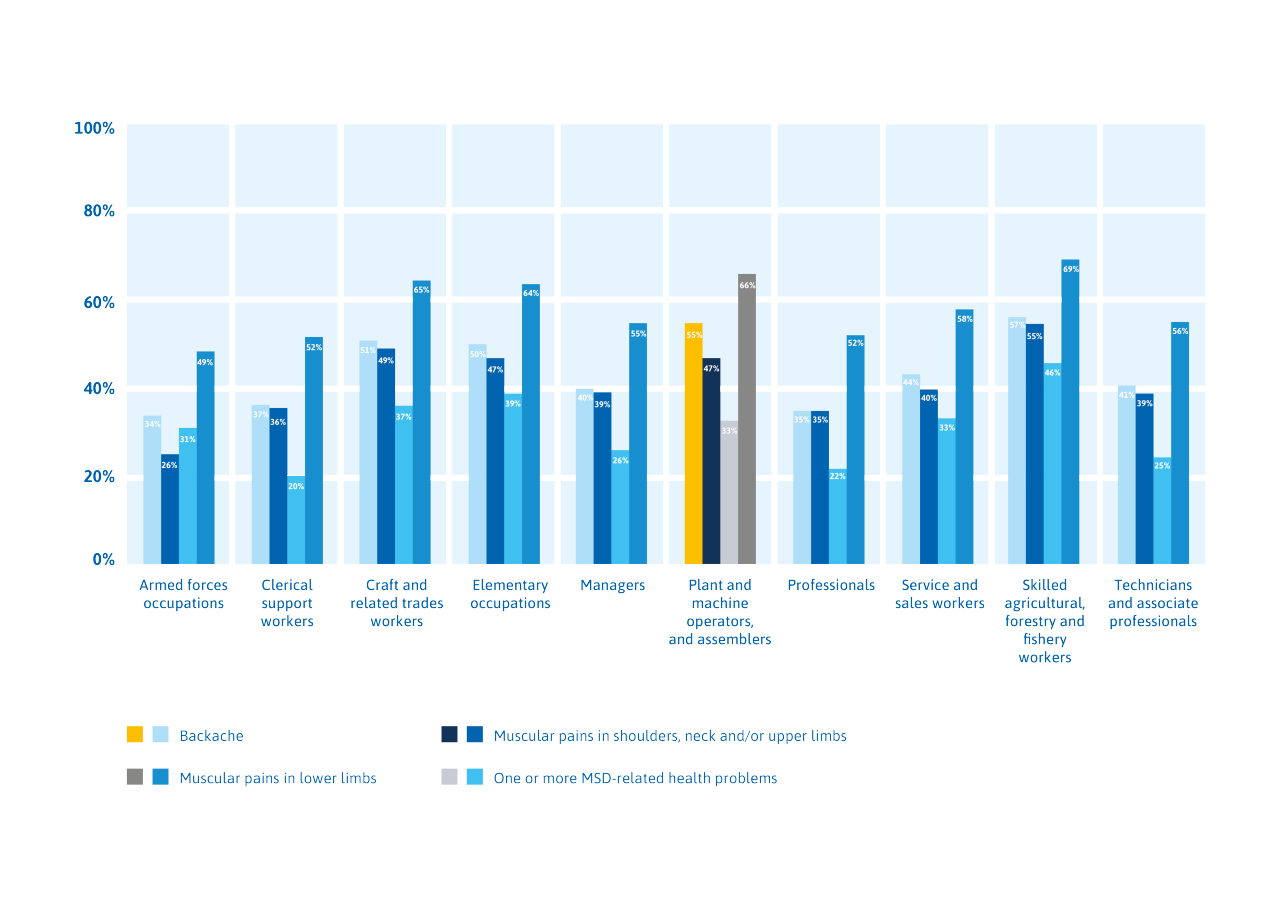

Musculoskeletal disorders (MSD) are the leading disability worldwide and the most common work-related health problem in Europe. In 2013, it was reported that 60% of workers in plant and machine operations suffered from MSDs.1

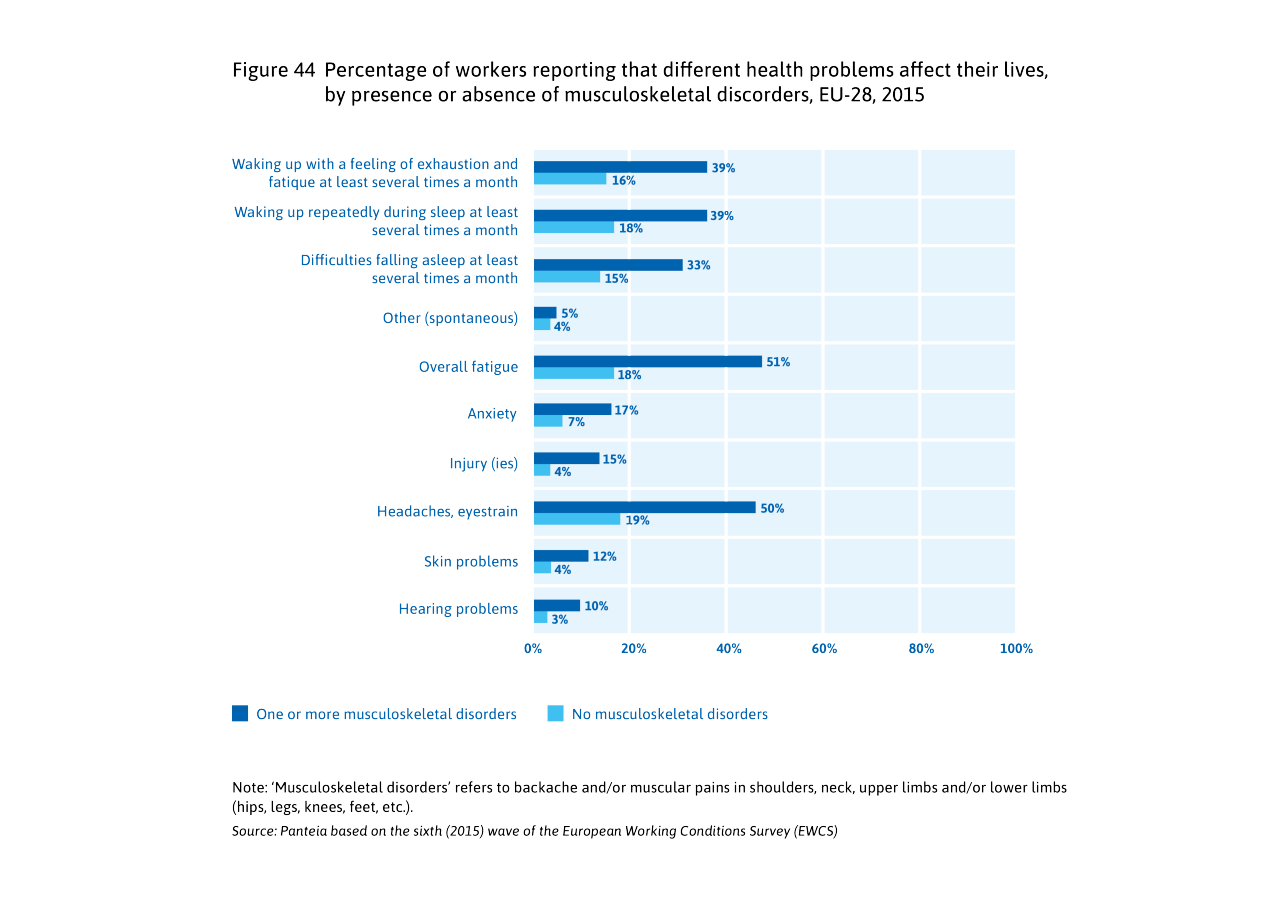

In addition, workers with MSDs are proportionately more affected by other health problems than those without MSDs, as shown in the figure below.

Establishing Ergonomics

To create a safe and healthy environment for workers, safety and operations managers in machine construction environments must apply an ergonomic workplace design as well as processes for the specific hazard types present and for the functions being performed. This is to use principles of a safety and health program to address MSD hazards and incorporate those principles into day-to-day operations.

The main objective of ergonomics is to adapt the work to the human being in order to reduce the drudgery and the risks in particular of MSD. This is done by adapting the environment: workplace and equipment, but also by analysing the workers' movements and the organization of the work. Ergonomic actions can improve the efficiency of workers and therefore productivity, although this is not an objective.

The machine building environment is a dynamic workplace with many hazards. It presents unique safety and ergonomic challenges. Designing an ergonomic work environment requires consideration of a wide range of factors, such as environmental factors ranging from machine layout to lighting conditions.

In many cases, operations and safety managers incorporate the use of safety gloves as part of a program to reduce the risk of hand or arm injuries. However, the addition of any safety equipment may decrease one short-term risk (injury risk) while increasing another medium- to long-term risk (MSD risk). Problems arise when the chosen solution does not meet the overall safety requirements.

The problem

In most machine construction environments, repetitive manual tasks are an unavoidable daily requirement, with workers performing labour-intensive activities such as moving and carrying, lifting and lowering, pushing and pulling, repeated turning, tightening of screws, as well as holding and restraining tools for installation of bearings. Tasks that require repetitive hand and arm movement can lead to hand fatigue, which subsequently puts more stress on other parts of the body and can contribute to injury. Simple actions become hazardous activities through repetition, the use of sustained pressure or force, maintaining prolonged or awkward postures and by ongoing exposure to vibration, stressing the body and potentially leading to a wide range of MSDs.

What are Musculoskeletal Diseases (MSDs)?

MSDs are categorized as diseases from an imbalance between the body's capacities and the constraints to which it is exposed. Generally, they are either the result of gradual wear and tear (triggered by repetition) or brought on by sudden strenuous activity or unexpected movement. Performing manual tasks makes the hands and arms particularly susceptible to a range of conditions..

The three most common MSDs are:

- carpal tunnel syndrome in the wrist

- rotator cuff syndrome in the shoulder

- lateral epicondylitis in the elbow.

Most of these can additionally present as acute or enduring chronic conditions that continue to threaten productivity in the longer term.

The cost

The true economic cost of workplace injury is more than lost wages or time. Ongoing medical expenses, lowered production and increased workers’ compensation premiums are among the more obvious and measurable aspects, but there are often hidden costs as well.

Though harder to measure, but MSD have significant repercussion for workers and for the company. The risk of MSDs increases with age, and older employees are often the source of expertise that is critical to maintaining a company's productivity.

The challenge

While conducting recurring or repetitive tasks is known to place strain on the muscles, nerves and tendons in a worker’s hands, performing those same activities while wearing gloves that are thick, rigid, ill-fitting, slippery or otherwise uncomfortable will significantly exacerbate the problem.

To address these issues, safety and operations managers should opt for a protective glove style designed for the specific hazard types present and for the functions being performed. This means considering multiple factors;

- FIT

Gloves that are too small generate more bio-mechanical stress, which increases the risk of RSI.

Gloves that are too large reduce precision, require more force during handling, with an increased risk of dropping the handled objects, compensated by a repetition of gestures. This leads to an increase in muscle fatigue and the risk of MSD. - GRIP

Handling an object requires strength to grip it before lifting it. Thus, an increase in grip brings more precision with less force. This reduces muscle fatigue and the risk of MSDs, especially during repetitive motions.

- DESIGN the materials, design of the gloves and comfort will dictate overall wearability.

Materials that are more resistant to abrasion make it possible to produce gloves that are just as effective while being more flexible and therefore less restrictive. In addition, there are ergonomic design criteria that improve glove accuracy and comfort such as: offset pinky, ogive-shaped fingertips or design from a 3D hand model specific to the curve of the right or left hand. - APPLICATION-SPECIFIC ISSUES wet conditions, contact with abrasive materials or the use of vibrating machinery, for example, all present differing needs. Each application is unique and should be assessed by an application engineer in its own context to determine the optimal glove choice. A solution is effective when it fits the context

Selection will vary based on these — and other — factors, but it is vital that the glove selection process includes an assessment of the effect on manual performance, ensuring that workers can operate both safely and efficiently. Through our partnership with ERIKS, we can provide you with an assessment of your workplace and needs to help you select the right solutions.

Ergonomic solutions

Workers are no longer forced to choose between comfort or protection, as new advances in glove technology deliver superior hand protection while providing much-needed support for musculoskeletal health.

ERGOFORM™ is a new technology that enables Ansell to design hand protection that supports musculoskeletal health during repetitive tasks and has been scientifically proven to deliver measurable improvements in worker comfort, fit and productivity while reducing the risk factors associated with ergonomic injury.

Ansell measures the toll of occupational activities and applies cutting-edge technologies to produce gloves. By electing to implement the use of ergonomically designed protective gloves, employers, managers, and operators can significantly minimise the risk of MSD injury, effectively support safety compliance, ensure productivity levels remain intact and above all, guarantee the security of the most valuable asset of any company: its personnel.

Sources:

- 1 European Working Conditions Survey 2016 (EWCS)

- 2 Eurostat, Labour Force Survey ad hoc module ‘Accidents at work and other work-related health problems’ (2013). All EU Member States participated in this ad hoc module except for the Netherlands.

- 3 Panteia based on the sixth (2015) wave of the European Working Conditions Survey (EWCS)

- 4 OSHA, osha.gov

General contact ERIKS Global Head Office

Chamber of Commerce

37 01 32 89

VAT Number

NL003.076.490.B02