Designing custom seals

How can Design for Six Sigma (DFSS) help you design a rubber seal?

Designing a custom seal or any other rubber seal requires careful consideration. Start by searching for a suitable compound, an elastomer specially developed for your specific application. Depending on the complexity of the project, it may be necessary to create a die or special tools.

This process is too often underestimated in terms of time and importance. A joint is considered a detail when designing a machine. A seal is much more than just a "connecting element". The wrong choice of material or type of seal can quickly lead to delays in the (design) process. Fortunately, it is possible to do things differently. With Design for Six Sigma, gaskets always find their place in a machine or component.

Design quickly and perfectly with Design for Six Sigma

Are you looking for a working method that streamlines (production) processes and ensures that products meet all requirements? Then Design for Six Sigma as an approach and philosophy is a good solution to make the right choices early in the design process. Statistics, risk analysis, proper documentation and measurable results help you design the perfect joint.

With Design for Six Sigma, design challenges are concrete and measurable from the start. The focus is on quality from the very beginning of the design process. This avoids mistakes in later phases. This approach reduces the time and costs involved in completing a project (or part of a project). If you thoroughly test, measure and verify the design with Design for Six Sigma, you can:

- Bring to market in a very short time

- Deliver high quality solutions

- Develop a more cost-effective way of working

Do you need advice on finding the right seal?

DMAIC or DIDOV: existing design or new design?

There are two different methods in Design for Six Sigma. One is suitable for developing new components (proactive), the other for improving an existing product (reactive). Both methods can be used for the development of seals for machines and components, such as custom O-rings.

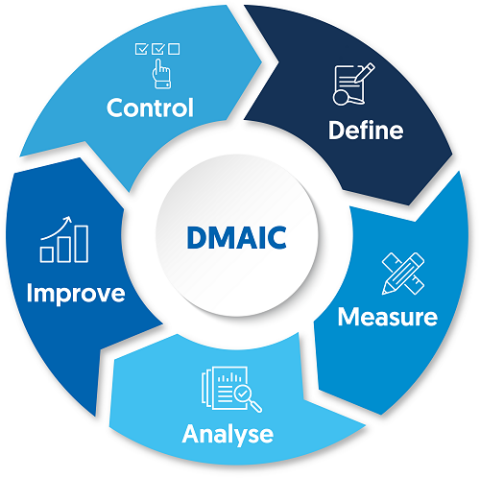

DMAIC - Define, Measure, Analyse, Improve, Control

It can be useful to optimise the design of an existing machine, for example by improving the seals. In this case, the DMAIC method is the best approach to make improvements in collaboration with your supplier.

The DMAIC approach is preferred when, in the context of new product development, it is more appropriate to modify the design (of a specific component) than to start from scratch. DMAIC stands for:

- Define

- Measure

- Analysis (Analyse)

- Improve

- Control

The reactive approach is clearly reflected in the last four steps. In the Measure phase, you measure the performance of the design in its current phase, then analyse, improve and control it. Without an existing design, this approach is not possible.

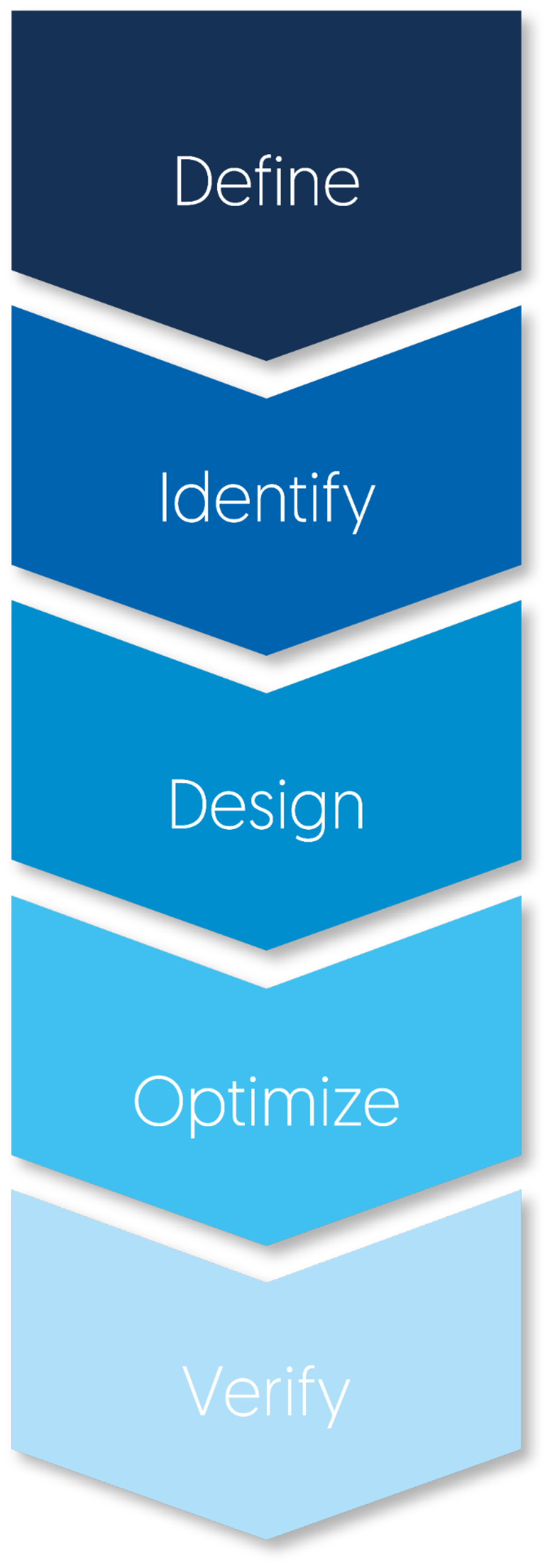

DIDOV - Define, Identify, Design, Optimize, Verify

With the DIDOV method, you develop new joints or other parts, adapted to your design. When, for example, certain tolerance levels cannot be achieved according to standard norms, the DIDOV method acts as guidance in the design process. At the beginning of the process, the project team accurately identifies the risks and requirements of the joints.

This method reduces problems and offers a better end result, especially if you involve your supplier at the beginning of the process. Because the risks and requirements are determined and tested thoroughly beforehand, you can be sure of a high-quality custom-made O-ring and can minimise the risk of design errors. DIDOV stands for:

- Define - This is where you define exactly what you want from your design as a whole and its individual components. CAD drawings and technical drawings are reviewed, as well as the requirements and wishes expressed in meetings, letters and other documents. All of this data is called the 'Voice of the Customer', a document in which all these requirements are summarised.

- Identify -The Voice of the Customer document is then used to define the specific requirements for the design. These are the CTQ elements, or 'Critical to Quality'. These CTQs are a transcription of the general requirements into technical requirements against which you must test and evaluate the design.

- Design - In the design phase, you develop the first version of the complete design and the individual components. By means of simulations and prototypes, you check that the design meets all the CTQs.

- Optimize - With the test results in hand, you optimize the design in this phase. New versions are created for components whose performance is not yet optimal. You continue in this way until your design meets all requirements.

- Verify - The last step before the zero series. In this phase you check the whole design one last time. Are the values correct? Is the process safe? Is everything working properly? In short, you check that the design meets expectations.

This process results in a fully validated project and avoids the need to redo everything. The extra time invested at the beginning of the design process is more than worthwhile.

Do you need advice on finding the right seal?

Related articles

Kontakt

Direktkontakt

Sie möchten mit einem unserer Mitarbeiter oder Experten persönlich sprechen? Zögern Sie nicht, kontaktieren Sie uns

Allgemeiner Kontakt

Nehmen Sie Kontakt mit uns auf. Bitte füllen Sie unser Online-Formular aus, wir werden Ihnen schnellstmöglich antworten.