In this article

3D printing supports innovation

ERIKS supports customers in making high-quality products. 3D printing is an important tool in producing complex parts used in systems and machines. In this article, we tell you exactly what 3D printing is used for and what benefits it brings to our customers. We also give a few examples showing how 3D printing contributes to innovation and optimisation of production processes.

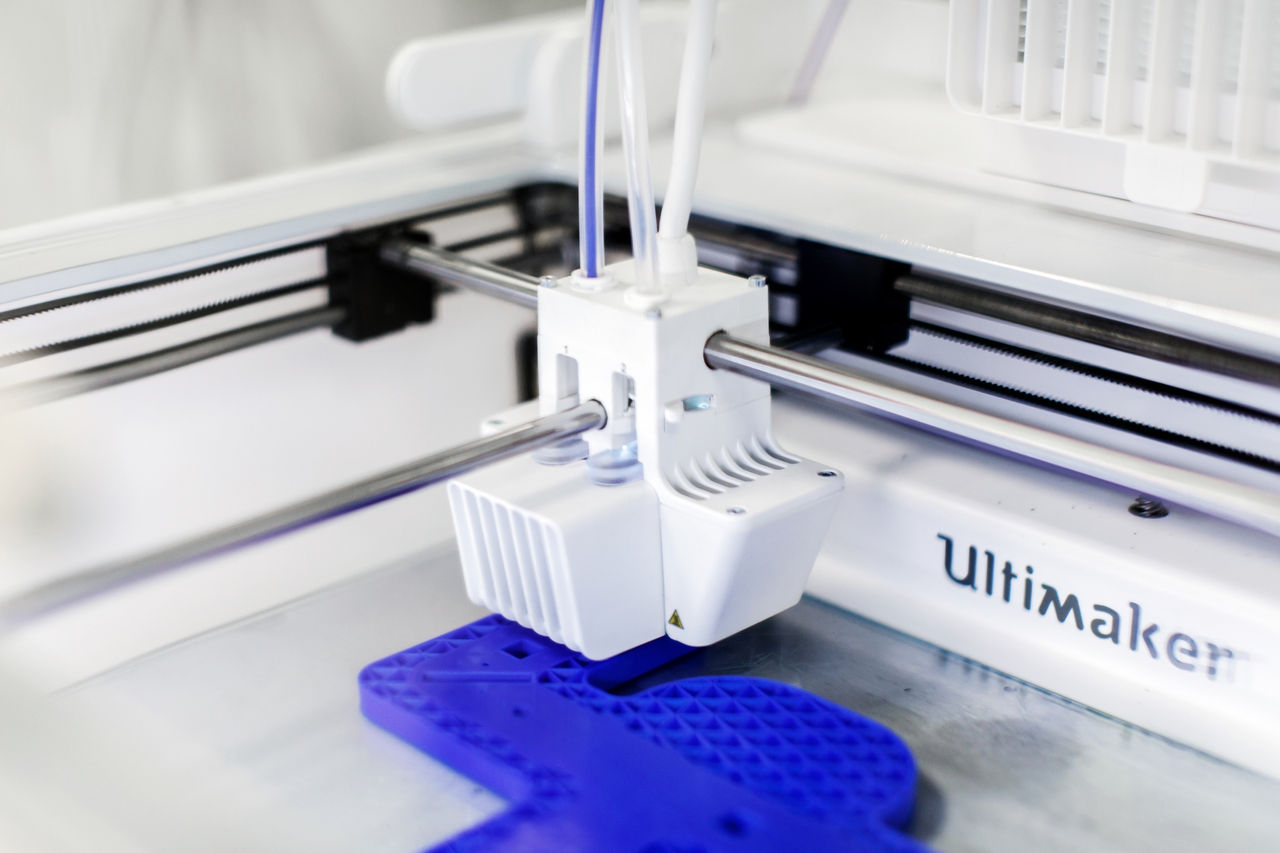

3D printing briefly explained

3D printing, also known as Additive Manufacturing, is a very efficient way of manufacturing if you compare it to other production methods. This is because with 3D printing, you only use the material you need. As a result, you don't waste unnecessary material, which makes for a sustainable and environmentally conscious way of production. Unlike 'normal' production by machining, with which you take a piece of material and remove what you don't need to arrive at a part/product. Actually the opposite of additive and thus much more cost-intensive and less sustainable.

What is 3D printing used for?

3D printing is mainly used by ERIKS as a tool for developing its own products. For example, in making dampers from complex rubber-metal parts for the semicon industry. In that process, the metal has to be sandblasted well to get a rough surface to which the rubber can adhere well. Using 3D printing, you can produce a customised mask part so that you only reveal the sides you need to sandblast. For example, ASML's machines move very fast and to stop those moving parts properly, you need dampers to control those movements. It is important that the machine is completely silent during exposure and free of vibrations. As people want to increase the capacity of the machines, speeds and accelerations increase, which gives challenges in controlling the vibrations. To reduce vibrations, viscous dampers are increasingly being used. With shorter machine lead time and increased production time as efficient results.

3D printing also supports the creation of tools for the quality department. For example, creating a jig/holder, which allows you to clamp an object and view it from certain sides. A jig is also suitable for positioning several products at once that allows you to perform an operation on several parts at once. Think of bundling tubes, after which they can be easily welded.

Advantages of 3D printing

3D printing offers unprecedented possibilities that other manufacturing techniques do not have. Its biggest advantage is that 3D printing allows you to make something quickly, even when it comes to complex and organic shapes, internal structures and passages or when new functionalities need to be added to a product. This significantly shortens the iterative process of arriving at a suitable end product. Ideal, for example, for making small series of complex parts when making adjustments to the production line. By applying 3D printing in this, the uptime of your production is guaranteed. In addition, 3D printing contributes greatly to the first-time-right principle. 3D printers use advanced technology and can produce an increasing number of different shapes and materials, so that the quality of the end result is optimal and meets all desired norms and standards.

Besides speeding up the development process, 3D printing also contributes to significant cost savings. During production, material is used extremely efficiently and the speed of development with 3D printing means that you no longer need to keep stock of material and spare parts physically but can digitise them. With Printing on Demand, parts are printed only when they are needed, ensuring permanently low stock levels and less space and capital requirements.

The added value of ERIKS

3D printing plays a particular role in developing complex rubber-metal parts for parts and products. These end products are used again by ERIKS customers in their production process. For example, it is widely used to develop jigs & fixtures. This is the case when parts need to be blasted. If you bond metal to rubber, you need a rough surface. But you only want that on the bonding surface. For everything around it, you don't want that. With 3D printing, it is possible to make a mould, where the metal piece clamps in and only the bonding surface sticks out. Which you can then blast, without damaging the rest.

3D printing also optimally supports ERIKS in the co-engineering process with the customer. To produce a rubber or rubber metal part, a mould must first be made. 3D-prints help to answer customers' questions directly and to be able to make desired modifications on the spot. Which, in turn, ERIKS can use in the conversation with the mould maker.

3D printing of Dampers, in collaboration with TNO

TNO is collaborating on the development of the smallCAT, a laser communication system that is on the Norwegian spacecraft NORSAT. To ensure optimum vibration reduction, TNO asked us if we could make dampers suitable for the system and the extreme factors in which it has to operate. On behalf of TNO, we used 3D printing to develop titanium dampers into which we vulcanised our rubbers. The applied rubbers were developed at our Lab ERT in Deventer. TNO finally tested the result, with the material meeting the required high viscosity damping, having a low outgassing value and also being very clean.

From experience, ERIKS knew it was possible to help TNO with this case. In fact, similar material had been developed at an earlier stage for ASML Netherlands. To fit as much information as possible on the smallest possible surface area, they use different systems at ASML, such as EUV (Extreme Ultraviolet) machines and XT machines. The material we use, SCVBR, is successfully used in several places in these machines for damping vibrations. Essential for error-free and efficient production.

Interested in learning more about 3D printing possibilities and how ERIKS can implement it to enhance your production efficiency? Get in touch with us.

Subscribe to our newsletter:

For the latest industry news and updates.