ERIKS is a member of Circles of Life

ERIKS is an active member of Circles of Life: an EU-funded collaboration that makes sustainability i...

Vendor Managed Inventory (VMI) is a system for a supplier to keep stock replenished, based on levels of consumption.

The aim of VMI is that the right products are always available, while reducing the customer’s input and admin.

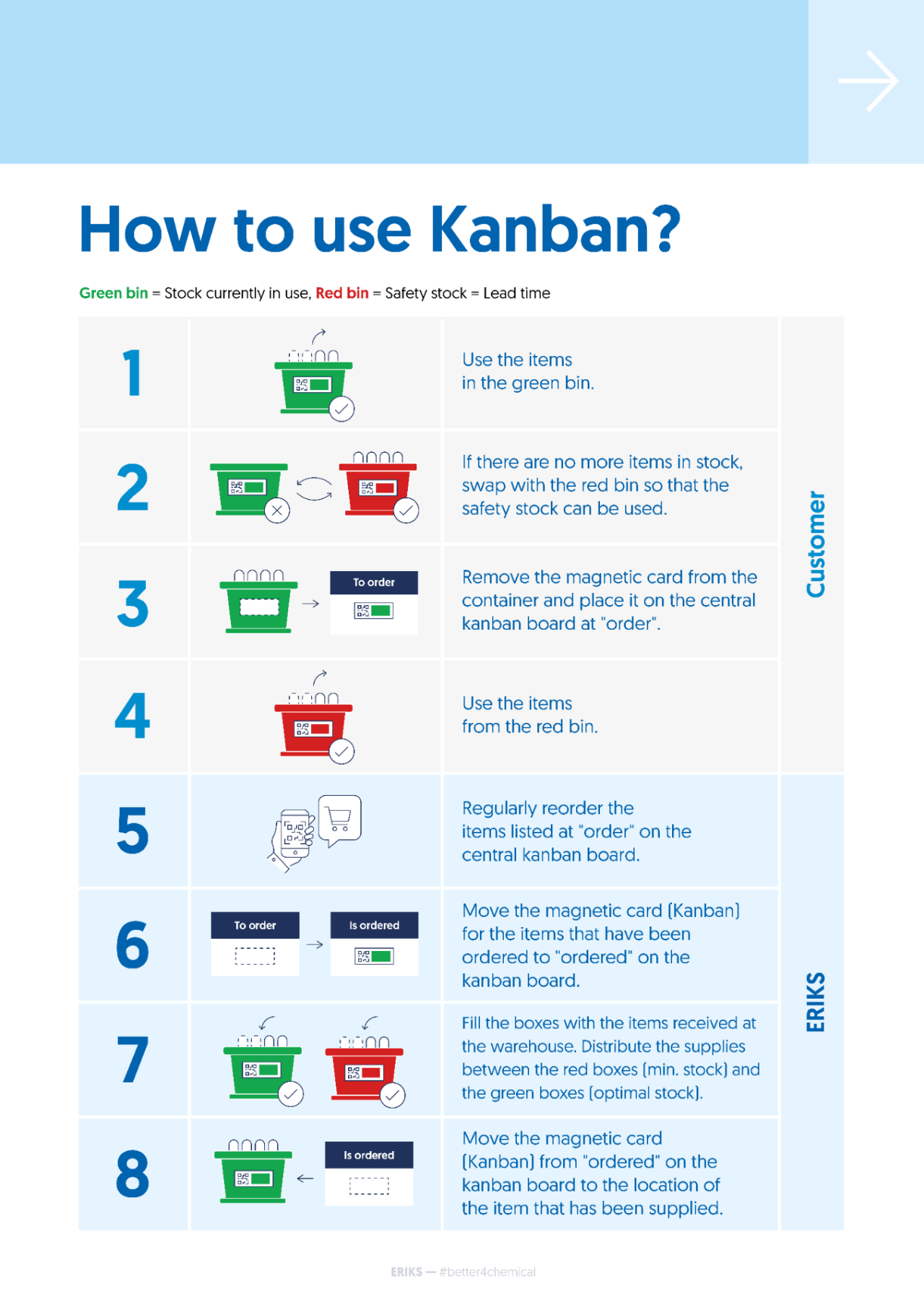

2-bin Kanban system of stock replenishment

VMI often works through a simple yet effective 2-bin kanban system. Say that 20 units of a particular bolt are used every week. 2 bins are then arranged in sequence, holding 20 bolts each.

When the front bin is empty it’s placed on the top shelf indicating that the stock needs replenishing. The second bin (still full of bolts) is then moved forward to be the first in sequence and used immediately while the empty bin waits for a new delivery. Once the stock of the empty bin is replenished it will be placed behind the still full bin (FIFO) to be the next in sequence.

All bins contain a barcode. When the VMI service worker arrives at your plant he collects and scans all empty bins. This results automatically in an order to replenish the empty stock. Throughout this process no input from an in-house stock manager is required.

VMI benefits include:

Typical VMI items for chemical plant customers are generally high turnover, regular consumption and low value articles. These can include bolts, fasteners, PPE, gaskets, glues, cleaning solutions, and dust caps. Bins are helpfully arranged in product “families” so they are easy to find when required.

A 1-bin kanban system is also possible, but as it requires a logistics worker to check every single bin to see if it needs replenishing, we recommend the 2-bin solution.

VMI is an excellent solution to streamline processes. There are ways of utilising VMI that can optimise stock levels and reduce TCO even further:

A helpful starting point for a good VMI is using product consumption history. This could be:

This data (ideally a combination of all three) is then used to build up a solid VMI system where stock levels are optimal right from the start. Data from, say, 3 years usually gives a much more reliable picture than a few months’ worth.

From this reliable inventory, you can evaluate what articles are really critical for the smooth running of the plant.

By organising your space for a VMI system you’ll store your items more efficiently and your VMI will work better. This involves:

Optimised space also means you can easily see what items you currently have, and help identify what extra items you need to complete your range, such as all necessary kinds of bolt.

There may be 15 different sorts of gaskets that your chemical plant needs to keep in stock. By having good storage space these gaskets will be secure and easily accessible.

Much of the time in the chemical industry, storage is in a central warehouse accessed by several production units. This increases costly walking time to and from the central store.

Decentralising storage means keeping a small assortment of frequently used or critical parts nearby to save time.

For best practice, don’t give each decentralised warehouse its own ability to organise its stock. You must maintain central oversight of total stock value and knowledge of what each area needs.

Set up a system for using older articles before newer ones. Some stock items like seals or gaskets have an expiry period, so using them before they go out of date will reduce cost of expired items.

A FIFO system encourages staff to put new items to the back of the hook so the older ones are taken first.

Colour codes are also useful. For example, reversible orange/blue gasket cards on the hooks can indicate which gaskets have been reordered and which need to be scanned for removal. Similarly, coloured sliders on bins can mark items as either scanned or due for replenishment. This is a quick, effective method of two-way communication between the supplier and the chemical plant mechanics.

VMI is a great way of guaranteeing available stock when it’s needed. It reduces labour-intensive, high-cost ordering processes for a net benefit to your TCO.

By allowing your vendor to manage your inventory, they’ll be able to tell you how best to arrange and manage your stock. Over time, the VMI data will get more accurate. This results in optimum stock levels and can also eliminate unused articles.

Following our best practices not only leads to good VMI – good VMI also leads to good practices, producing a positive feedback loop in your stock management processes.

ERIKS has an enormous range of (stocked) parts and expertise in setting up VMI for chemical industry customers. For instance, materials innovator DSM Dyneema were struggling to maintain their complex, labour-intensive warehouse management. ERIKS helped DSM standardise their items and ascertain their minimum stock levels. This in-depth consultation, combined with a robust 2-bin VMI system, allowed DSM to lower their administration, increase availability of items and reduce their TCO.

For further insight on how our expertise has benefited a real-life customer, read our DSM case study.

Take a look at our latest updates...

Want to speak directly with one of our employees or specialist? Don’t wait and get in touch

Get in contact with us. Please fill in our online form and we will contact you as soon as possible.