Joint monitoring

This ensures the expected life of the seals through proper assembly, maintenance and storage

You may be familiar with the saying that 'a chain is only as strong as its weakest link'. This principle can be applied to joints. After all, how is the seal - a small but essential part of the machine - treated after it leaves the factory?

Damage, leaks and other undesirable situations that can compromise the operation of your machine can be the result of incorrect assembly, maintenance or storage of a seal. Eliminate these risks and problems by considering proper assembly, maintenance and storage of seals early in the design process.

Assembly: avoid problems with seal assembly at the workplace

The assembly of joints is too often ignored during the design phase. "If you press hard enough, it will seal well," you may think. But later, pressing "hard enough" is not possible for production line staff.

The way the seal is mounted can also cause major seal failures, with all the safety risks that this leads to. The engineer must be very careful not to stretch the seal to the point where it becomes distorted or leaks. As an engineer, you can avoid this by thinking well in advance about the assembly and the place of the joints in your design. The development of specific tools and work instructions also helps to keep the joint in optimum condition.

Design the perfect seal for your machine, download the Sealing Guide.

Do you still want help to choose the right seal for your machine? In the Sealing Guide we detail the five most important points that you should not overlook. Ask for the Seal Guide and avoid rework, delays and other problems.

Maintenance: does the seal withstand the cleaning process?

The machine must be regularly maintained and occasionally cleaned intensively. Did you take this into account when designing your machine? If not, it is possible that the seals will break down more quickly than expected. For example, not all rubber seals are resistant to the cleaning agents and chemicals used in cleaning. Also think about steam cleaners: this hot steam can be disastrous for some types of rubber. So think about maintenance and cleaning of your machine when designing it. Let a technical expert work with you on this.

Storage: make sure your seals are still usable

A seal can last a long time, but not forever. The application of your machine has an influence on this. The way in which a seal is stored before it is mounted in the machine is also a determining factor. It is very important to think about this when choosing a suitable material. The life of a stored seal is influenced by the following factors:

- Temperature and humidity

- Light and ozone

- Contact with other environments

- Contact with metals and other rubbers

- Deformation

- Packaging materials

It is best to store seals in a dark, dry and cool place and in original packaging. Finally, it is important not to put anything on the joint that could deform it.

Think about the conditions in which your seals will be stored in advance and take this into account in the design process.

How does the ideal joint fit into your design process?

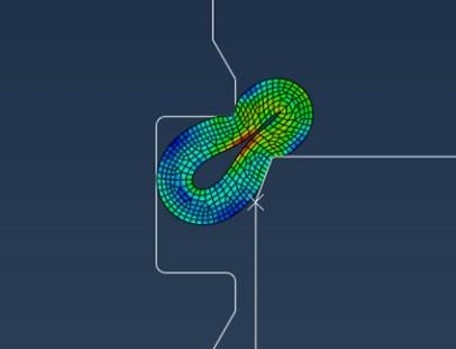

When choosing the right seal for your application, several aspects come into play, such as the pressure, environment and temperature to which the seal is exposed in the machine.

Assembly, maintenance and storage are equally important to ensure that the seal will perform for the duration of its desired lifespan. Think about this when designing a machine as it will avoid unnecessary wear and tear and all the associated risks.

Related articles

Kontakt

Direktkontakt

Sie möchten mit einem unserer Mitarbeiter oder Experten persönlich sprechen? Zögern Sie nicht, kontaktieren Sie uns

Allgemeiner Kontakt

Nehmen Sie Kontakt mit uns auf. Bitte füllen Sie unser Online-Formular aus, wir werden Ihnen schnellstmöglich antworten.