In this article

Complex projects require customisation

ERIKS is a leader in providing engineering solutions, using innovative techniques and strong technical expertise. The Engineering Department of the Flow Control Business Unit plays a central role in supporting customers, from offering advice to developing customized solutions for their production environments. Martijn van Wijk, Product Development Manager Semicon within Engineering, explains through several case studies how ERIKS addresses complex technical challenges and turns them into complete solutions, effectively taking the burden off the customer.

ERIKS supports greater customer focus

Over a decade ago, the Engineering department was born out of our customers' need to focus more on their own overarching product or service. Products are becoming increasingly complex and with that it is becoming increasingly difficult to have and maintain knowledge on every sub-component. A trend that is still visible. Think, for example, of OEMs in the semicon industry, where machines are getting bigger and more complex. ERIKS has a lot of expertise in individual components, but also in putting together complete assemblies. By outsourcing the production of such modules to ERIKS, these manufacturing companies can focus more on the design and assembly of these complex machines.

ERIKS' experts handle a wide range of customer inquiries. Often, these aren't just individual questions but part of a larger problem where the customer is seeking broader advice. Engineering focuses on connecting these inquiries and providing integrated system solutions.

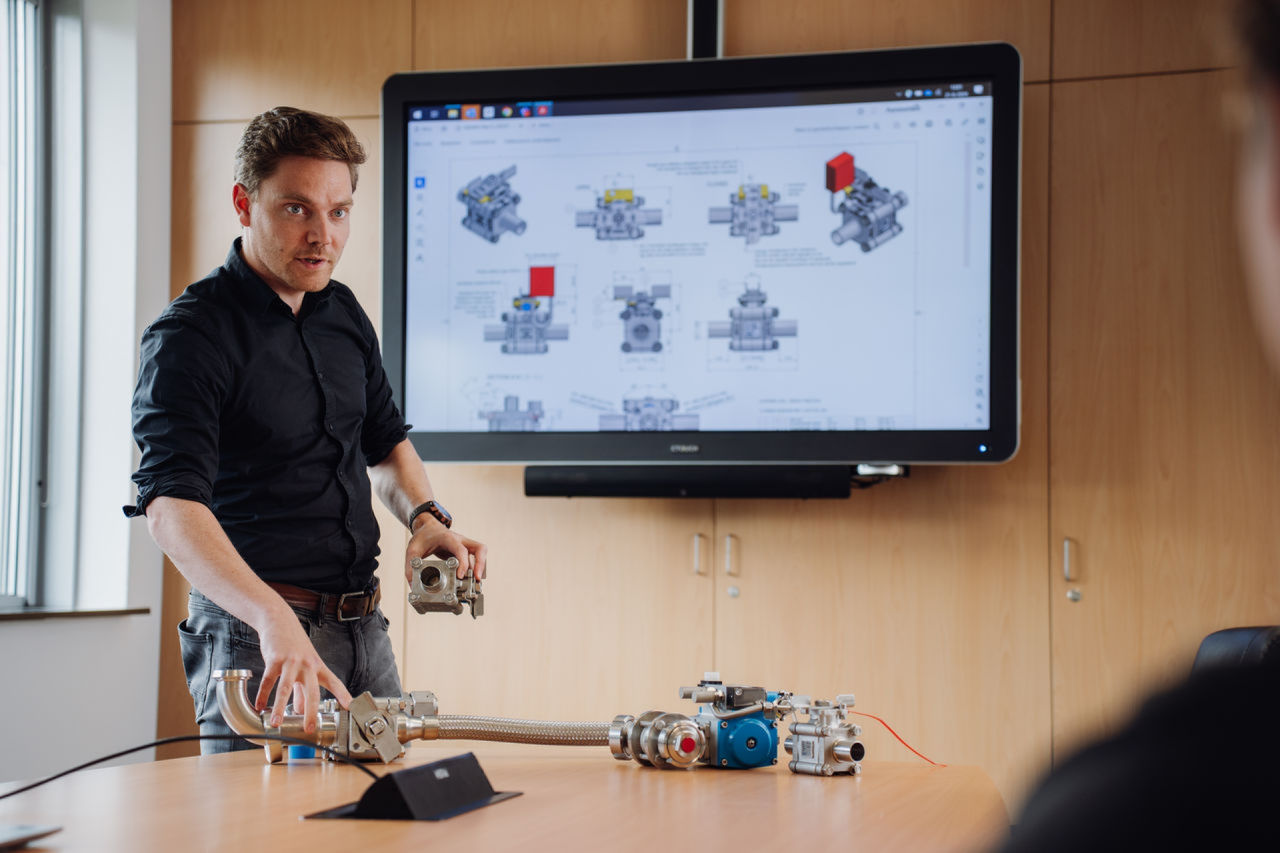

"I started as a Project Engineer," Martijn explains. "In this role, I had the responsibility of getting the different departments within ERIKS to work together on one overall project. Think of valves, seals, measurement and control technology for different applications in, for example, steam, water or high-pressure gas. As a department, we bridge the gap between the various disciplines within ERIKS.

Finding the right solution together with the customer

For most ERIKS customers, the biggest challenge is finding the right balance between time, cost, and quality. Growing competition among OEMs also requires faster time-to-market and improved quality, which puts pressure on our development and delivery timelines. We take this burden off the customer by providing sustainable solutions.

Engineering's working method fits seamlessly with the challenges customers face. "Where ERIKS makes a difference is that we really think along with the customer in getting to the heart of the problem," Martijn explains. "Consequently, with our broad knowledge of the industry, you can see that we often come up with the most effective and pragmatic solution With this strong focus on co-engineering and the right guidance during the (in-house) assembly process, makes us successful with our customers."

Concrete steps towards a comprehensive solution

"The projects where we are most successful typically involve optimizing production processes. For example, a machine may need water heated to a specific pressure, which can be achieved in various ways. That's where Engineering steps in. I am often brought in early and aim to visit the customer's site as soon as possible. What are the customer's needs? How is the process structured? How are the machines designed? By understanding the entire process, we can identify critical components and deliver a targeted, pragmatic solution."

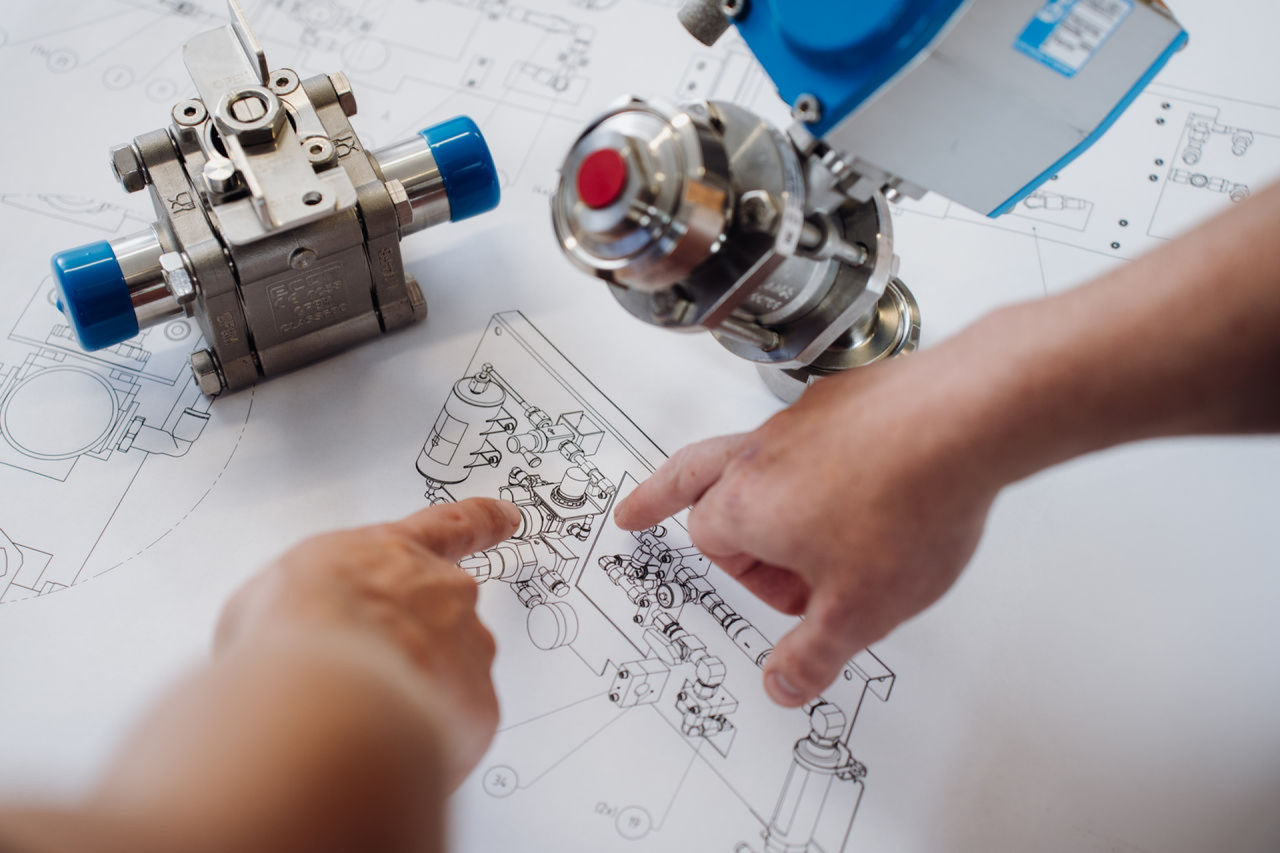

Martijn emphasizes the importance of strong collaboration with the client, which he sees as the foundation for successful implementation. Co-engineering is key, where decisions are made together with the client. Factors like material, temperature, flow, the quality of the incoming medium, and the quality of the outgoing medium are usually the main considerations. By clearly defining these factors, multiple issues can be addressed at once, resulting in a complete solution that balances time, cost and quality.

Engineering in practice

The engineering department at Flow Control develops two types of products. One-offs - which are unique solutions that occur once - and the series products, which are developed mainly for OEMs. In both cases, we substantially reduce the Total Cost of Ownership (TCO). One-off solutions are often cost-intensive to develop because specific expertise is required. By creating a product that makes the process work more efficiently, it sometimes pays for itself within a few months. With serial products, the focus is much more on creating a high-quality product and robust production process. This focus enables us to produce a 'reliable' product that is 'repeatable'. Besides production, our quality control process identifies any deviations or trends so that we can respond proactively throughout the product's life-cycle. In this way, the customer benefits from a stable supply chain for a long time and no longer has to worry about it.

Parts and machines for a complex production environment

Working with a global manufacturer of cocoa processing equipment provides a great example of developing a serial product. "The company used to source the parts for their machines themselves," Martijn explains. "They also assembled the entire machines, even though they had no time for it. It started with them asking us to help supply components for a new machine. Specifically, they needed a component that could bring steam, water, and air into the machine under the right conditions. To ease their burden, we immediately offered to develop and produce the entire system for them.

The first step was to collaborate on how the module could best meet their needs. The customer had a basic schematic, which we further developed. This was necessary to account for production factors like skew, proper dewatering, ensuring the correct quality of steam, water, and air, and fine-tuning the process. With our broad expertise in flow control, we were able to address all of these challenges effectively within the production process."

"In my view, this case clearly demonstrates the added value of ERIKS and our process: starting with a schematic, we collaborate to develop an engineered solution, and ultimately build it for the customer, in line with agreed terms and all relevant laws and regulations."

Specific expertise for a one-off

"New plants are frequently built at the Chemelot industrial estate. When construction begins, an engineering firm typically leads the project, but often the entire process hasn't been fully detailed. That's when they come to ERIKS. We take a process-oriented approach to determine what’s needed. The first step is creating a Piping & Instrumentation Diagram (P&ID) for the customer, which outlines the flow and the placement of valves. Once the customer approves the design, we provide the complete solution. We handle the final drawings and delivery, ensuring compliance with the set standards. This is a one-off, fully engineered solution developed in collaboration with the customer, built together in-house. As the final step, we support the installation process."

"This is a good example of how we unburden a customer from start to finish. We support the customer at the beginning of the process, but also with advice for the installation, commissioning and maintenance of the product. Think of a steam trap survey or training for the technical staff who have to use the system."

Shortened drying process due to self-regulating recirculation unit

"A raw material producer in the pharmaceutical industry was seeking a solution to shorten the drying process as much as possible, which is critical for starting the next batch," Martijn explains. "While higher temperatures speed up drying, they also increase the risk of product burning. The steam used in the process was difficult to control, leading to hotspots. Additionally, the customer wanted to regulate the steam more precisely over a wide range to experiment with the production of new products."

"By letting the steam first heat a water circuit and then using this water to heat and cool the machine, ERIKS chose an energy-efficient, precisely self-regulating solution: a cooling & heating skid. This skid pumps the water around at the right temperature. The advantage is that the product remains protected from excessive temperatures and the dryer is heated more accurately and evenly. The result: better control of the drying process and shorter drying and cooling times."

Unique ballast system for Çanakkale 1915 bridge

"Together with Strukton, ERIKS developed a ballast system for the controlled sinking of the concrete foundations, so-called caissons. These caissons were subsequently used to build the longest suspension bridge in the world, the Çanakkale 1915, in Turkey. The caissons for the pillars were built in a dry dock and weigh 66,000 tonnes each. Each caisson has the area of a football field and a height of a 10-storey apartment building. They consist of several compartments that were filled with water during sinking. The ERIKS ballast system consisted of a shipping container in which a skid was placed to allow controlled sinking. The skid consisted of many valves with actuators, hoses, a pump and a control cabinet and software and interface software. The ballast system features as many as 38 valves. These remote-controlled electric butterfly valves were connected via hoses to pipes embedded in the concrete of the caissons."

"Alongside co-engineering with Strukton, the ballast system is the result of close collaboration within ERIKS. A project group was formed to bring together all the relevant knowledge and experience. Through several design sessions, the sinking process was translated into a robust ballast system. This was a great project that showcased the full range of ERIKS' expertise."

Long-term technical partnership

"ERIKS is increasingly involved earlier in the development process, which aligns with our strategy. At the start of a project, multiple solution options are often still available, allowing us to provide greater value to the customer. We collaborate with our customers to develop technical roadmaps for our key segments: food, pharma, high-tech, semicon and maritime. This approach helps us enhance existing products and components with new technology and respond more quickly when challenges arise."

"This aligns with the co-engineering demands from the market, where customers are increasingly seeking added value. In this role, ERIKS is no longer just a supplier but serves as a technical partner and advisor."

Subscribe to our newsletter:

For the latest industry news and updates.