Chemical Resistance Guide

For more details about chemical resistance, please check our Rubber Chemical Resistance Guide.

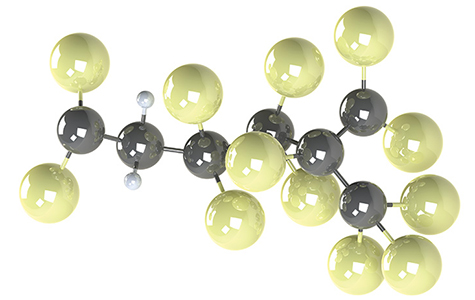

Fluorine Kautschuk Material (FKM) is related to fluorocarbon-based elastomer materials defined by ASTM International standard D1418 and ISO standard 1629. FKM polymer is made from vinylidene monomers (VDF) with a high concentration of fluorine and carbon-based monomers. It is commonly called fluorine rubber or fluoro-rubber. FKM and FPM are interchangeable abbreviations that often refer to the same family of fluorocarbon-based materials. In some countries, FPM is a more commonly used abbreviation. At ERIKS, we give priority to the ISO abbreviation: FKM.

Fluorocarbon elastomers have grown to major importance in the sealing industry. Due to its wide range of chemical compatibility, temperature range, low compression set, and excellent ageing characteristics, fluorocarbon rubber is one of the most significant single elastomers developed in recent history.

FKM and the Viton™ brand

FKM was originally developed by DuPont and Chemours under the brand name Viton™. Now several FKM manufactures exist, and some have their own brand names: Dai-El (Daikin), and Tecnoflon (Solvay). People often ask for ‘’viton’’, when they are specifically looking for the Viton™ brand. Dyneon®/Fluorel® (3M) is also a well known fluoroelastomer, but will be retracted from the market by 2025.

If you are looking for fluorine rubber materials for use in high-tech industries where low outgassing and low particle emissions of the materials are required, for example in the optics or semicon industries, then have a look at our SCVBR® offering.

FKM materials differ from each other by:

Generally, with increasing fluorine content, resistance to chemical attack is improved while low temperature characteristics are diminished. There are, however, specialty grade fluorocarbons that can provide high fluorine content with low temperature properties.

The differences have a significant impact on chemical resistance and temperature performance. The ASTM D1418 designation is a way of categorizing FKMs, but they are often named as type A-B-F-GF-GLT (type names defined by Chemours for the Viton™ brand).

ASTM D1418

Common Used Names

Cure System

Fluorine Content %

Description

Type 1

Viton™ A

Bisphenol or amine

66 %

General purpose with good compression set

Type 2

Viton™ B, F or GF

Bisphenol, amine or peroxide |

66-70 %

Improved solvent, coolant and hot water resistance

Type 3

Viton™ GLT |

Peroxide |

64-67 %

Improved low-temperature resistance, but reduced chemical resistance |

Type 4

Aflas® |

Peroxide |

55 %

Type 5

Viton™ ETP |

Peroxide |

67 %

Improved resistance to amines |

-

Ultra-Low Temp

Peroxide |

66 %

Improved low-temperature resistance compared to Type 3

For more details about chemical resistance, please check our Rubber Chemical Resistance Guide.

To guarantee the best quality for custom products, we work with Six Sigma engineering methods, Finite Element Analysis (FEA) simulations and special development processes.

ERIKS NV

P.O. Box 19108

3501 DC Utrecht

The Netherlands

E info@eriks.com

37 01 32 89

VAT Number

NL003.076.490.B02